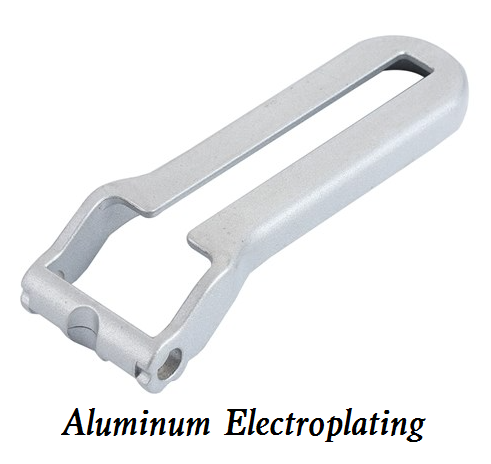

Aluminum castings can be electroplated to improve appearance and properties, in this article, we’ll get into the basics of aluminum electroplating, including advantages, process, plating types, and tips.

Advantages of Electroplating Aluminum

Aluminum has the advantages of good conductivity, fast heat transfer, easy forming, etc., but aluminum and aluminum alloys have the disadvantages of low hardness, no wear resistance, easy intergranular corrosion, difficult welding, etc., which affect their uses. Therefore, electroplating has been used to solve this problem in modern industry in order to develop advantages and avoid disadvantages.

– Improves decoration

– Improves surface hardness and wear resistance

– Reduces friction coefficient and improve lubrication.

– Improves surface conductivity.

– Improves corrosion resistance

– Makes it easier to weld

– Improves the adhesion with rubber during hot pressing.

– Improves reflectivity

– Repairs dimensional tolerance

The Process of Aluminum Electroplating

As aluminum is a relatively active metal, and the electroplated material is more active than aluminum, corresponding chemical conversion must be done before electroplatings, such as zinc dipping, zinc-iron alloy, zinc nickel alloy, and the intermediate cyanide copper plating layer that makes the zinc and zinc alloy bottom layer have good adhesion. Due to the loose structure of the die cast aluminum body, the surface of the body cannot be polished off, otherwise, pinholes, acid-spitting, peeling, and other phenomena will occur.

The simple process of aluminum plating:

Degreasing -> alkaline corrosion -> activation -> zinc replacement -> activation -> electroplating -> chromium plating or passivation -> drying

Types of Aluminum Electroplating

1) Black plating, such as black zinc, black nickel, etc. is used in optical electronics and medical devices.

2) Gold plating and silver plating are the best conductors of electronic products, and can also improve the high decoration of products, but they are expensive. They are generally used in the conductive aspects of electronic products, such as the electroplating of high-precision wire terminals.

3) Copper, nickel, and chromium are the most popular mixed plating species in the field of modern science. They are the most popular plating species in the world both in decoration and corrosion resistance. With low prices, can be used in sports equipment, lighting, and most of the electronic industry.

4) Among the copper plating species, white tin copper is developed in the 1970s and 1980s for environment-friendly plating species. It is bright white and is the first choice in the jewelry industry. Bronze (lead-tin copper can be used as imitation gold, so it is a better decorative plating type), but the anti-tarnish property of copper is relatively poor, so the development is relatively slow.

5) Zinc electroplating: the zinc coating is bluish-white, soluble in acid and alkali. As the standard potential of zinc is more negative than that of iron, it can provide reliable electrochemical protection for steel. Zinc can be selected as the protective layer for steel products used in the industrial atmosphere and marine atmospheres.

6) Hard chromium, the chromium coating deposited under certain conditions has high hardness and wear resistance, and the hardness reaches HV900-1200kg/mm. Chromium is the coating with the highest hardness among common coatings, which can improve the wear resistance of parts and prolong the service life. Such as tools, dies, gauges, fixtures, etc. Therefore, plating is an indispensable treatment for the cylinder, oil pressure, and transmission system.

Tips for Aluminum Electroplating

1) Aluminum alloy should be used as a hanger for electroplating aluminum parts.

2) Each process of aluminum and aluminum alloy after etching must be carried out quickly. The shorter the interval between processes, the better, to avoid re-oxidation.

3) The second zinc dipping time should not be too long to avoid excessive corrosion.

4) The water must be cleaned.

5) Prevent midway power failure during electroplating.