news

2022.3.9

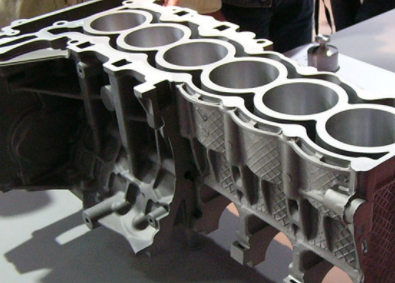

The sticking phenomenon of aluminum die casting has always been a difficult problem for die casting workers. Due to die sticking, many casting defects will be directly extended, such as casting quality problems such as surface strain, lack of meat, internal shrinkage and leakage caused by damage of surface dense layer. Therefore, die-casting practitioners need to make full prevention from the process design stage of die-casting die, die surface treatment, manufacturing and maintenance, die-casting production process control, and other aspects, so as to minimize and control the probability of die sticking. The following is a specific analysis from the above aspects combined with actual cases.

Design of inner gate angle

When designing the inner gate, the aluminum alloy liquid should be avoided from entering the mold cavity at a relatively large angle to reduce the direct scouring of the cavity wall by the alloy liquid. This kind of die sticking castings will be scrapped due to out of tolerance of casting wall thickness and lack of meat after casting quality inspection. The casting cavity is deep. In order to facilitate mold filling, the development process of the casting cavity covering the fixed mold side is adopted. The fixed mold uses a false slider to ensure the demoulding of the follow-up mold, and the sprue can only be designed on the fixed mold side. In order to improve the previous sprue design process, due to the relatively large angle of the inner gate, the sprue is in the form of direct punching with the inner gate directly against the mold cavity wall, resulting in serious die sticking problems. Due to die sticking, the die has to be polished frequently, and the protruding surface of the fixed die forms an inverted buckle, which further aggravates the problems of die sticking and drawing.

In order to improve the design process, the sprue angle is adjusted from 180 ° to 120 ° – 130 °, the inner gate surface is poured parallel to the wall surface of the cavity, and then the feeding angle of the inner gate is adjusted between 60 ° – 75 °. Through the field die-casting production verification, this kind of die sticking problem has been significantly improved.

Local cooling design

For hot spots and isolated islands in the mold cavity and thick parts of the casting, a point cooling process should be added inside the mold to eliminate the die sticking caused by excessive local temperature of the mold. When the temperature of the die becomes very high, resulting in the reaction between the aluminum alloy and the die, and the compound on the contact surface becomes an aluminum iron mixture, the die sticking phenomenon will occur. With the increase of the cold and hot cycle of die-casting spraying and the number of injection molds, the viscosity modulus will also increase, and the accumulation on the die surface will increase at the same time, aggravating and attenuating the thermal conductivity of the hot spot of the isolated island of the die, Die sticking is becoming more and more serious. More serious results will make the casting bonded to the mold and it is difficult to separate the casting from the mold. Through the naked eye, it can be observed that the surface of the die cavity is adhered with a layer of coating similar to white powder, which directly destroys the surface dense layer of the die casting itself, resulting in quality defects such as leakage in the air tightness test of the casting.

An engine oil pan integrated with the installation position of the oil filter. During the early process design, the solidification analysis found that there was thick heat in the installation position of the oil filter. Combined with the analysis of the early die sticking problem caused by the similar Island hot joint, the overall model of this part was changed to the mosaic structure design, and the interior was cooled by “U” type circulating water. The production practice shows that this scheme eliminates the problem of die sticking caused by isolated hot spots in the die cavity, and the dense layer on the surface of the casting is excellent. At the same time, it also solves the quality problem of air tightness detection leakage here.

Internal design and spraying structure of mould

In the current automatic die casting production process, robots and manipulators have replaced manual spraying. There are inevitably some spraying dead corners in the mold cavity formed due to the casting structure. To solve this kind of mold sticking problem caused by inadequate spraying lubrication, in addition to designing profiling spraying module according to the mold cavity on the automatic spraying module, By designing the spraying structure inside the mold, the sticking problem of spraying dead corner can also be prevented.

The forming part of the casting on the mating surface of the sliding block and the moving die core is a spraying dead angle, which is a dead point that can not be effectively sprayed through the spraying manipulator and profiling spraying module. In order to solve the die sticking problem caused by inadequate spraying. During the mold design, two nozzle designs in the mold are added. The spray head is connected with the spray system pipeline to achieve the synchronous spraying effect with the spraying manipulator, and the spraying angle and spraying distance are relatively better. The die sticking problem of spraying dead center is well solved.

H13 steel is usually used as the steel of die core, and the steel is quenched and tempered to make the steel hardness reach 46-50hrc. Under normal circumstances, the mechanical properties of H13 steel can not only meet the requirements of heat fatigue resistance, but also have a certain thermal stability. The surface of the mold cavity is coated with special materials with high melting point to form a coating layer to avoid die sticking, such as molybdenum based alloy, which can be mixed with iron and bonded to the position where die sticking occurs on the mold surface; You can also use various materials to prevent die sticking at the die sticking position to treat the die surface, such as metal tungsten; The surface treatment of the die by physical method (PVD) can effectively prevent the occurrence of die sticking, such as Cr n + W, on, (Ti Al) n and CRC.

A mold cavity insert coated with metal tungsten by cold welding. The insert is located on the side of the gate. Due to structural constraints, internal cooling cannot be realized, and due to the high-speed and high-pressure scouring of the molten liquid, the protective film formed by spraying and lubricating the external release agent will be quickly brushed off during injection filling, resulting in frequent die sticking. After being coated with metal tungsten, the surface is relatively rough, which can effectively lock the demoulding lubricant on the forming surface of the insert without being washed away by the liquid aluminum, which can ensure that the problem of die sticking can be well improved within 2000 die times. More sets of inserts need to be prepared for mold maintenance. Designed as a quick change structure, once the coating is washed out, it can quickly replace the re coated insert through maintenance in the shortest time.

Fe content in aluminum alloy has strong affinity with iron in die

If the iron content in the aluminum alloy is insufficient, it is easy to bond in the cavity of H13 material mold. Iron is a harmful element in molten aluminum alloy. Therefore, with the increase of iron content, the mechanical properties will decline, especially the impact toughness and plasticity will decrease, the hot cracking tendency will increase, the aluminum alloy will have hard spots and the processing properties will deteriorate. However, iron can reduce the die sticking tendency of aluminum alloy and facilitate die casting. Therefore, the content of iron in die-casting aluminum alloy should be controlled within a certain range. The practice has proved that controlling the content of iron in die-casting process at 0.7-1% has a certain effect on improving die adhesion.

Process parameters

Too high temperature of molten aluminum, too high speed of inner gate, and too high injection specific pressure will also lead to die sticking problems. The higher temperature of molten aluminum will lead to higher die temperature, and chemical reaction between die and molten metal will lead to die sticking. Higher inner gate speed will make the microstructure of the casting porous and significantly reduce the mechanical properties. Therefore, for castings with high requirements for internal quality, mechanical properties, and compactness, it is not suitable to select large internal gate speed, and also use to prevent the occurrence of die sticking. At the same time, the casting pressure, pressure holding, and mold retention cooling time are reasonably calculated and set according to the performance requirements of the casting, so as to effectively feed before the metal melt begins to solidify.

Release agent

High quality die casting release agent can reduce the occurrence of die sticking through reasonable proportion. At present, the die casting industry has not issued a unified standard for the release agent, and the international community, including the most authoritative North American Die Casting Association, has not published a unified inspection standard for the application of release agent. Technicians should strictly control the brand of release agent, that is, select suppliers with good reputation, strong capital and technical force, high technical service level and stable quality. Once selected and tried, it is effective to prevent mold sticking. Do not easily change the brand of release agent.

In addition to the above three measures to prevent die sticking, the structural design of die castings should also fully consider that the castings have sufficient casting inclination and uniform wall thickness transition, and the boss should avoid forming a thick island shape as far as possible.

Die casting die sticking problem is the result of many factors, which is difficult to completely avoid. However, through the innovation of die casting die process design, the application of new die surface treatment technology, and the combination of production process control and practice, the die sticking issue can be well prevented and controlled.