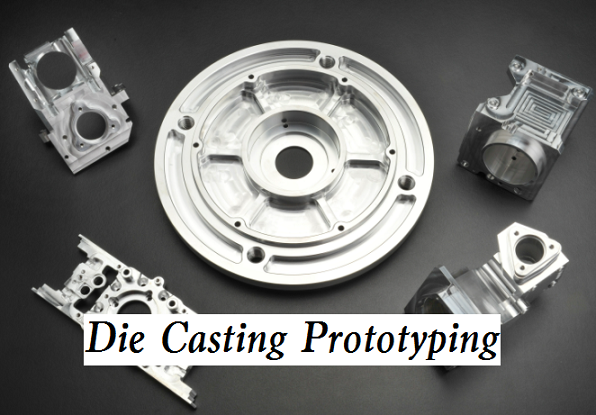

Prototyping is an important step in the die casting process, as it allows manufacturers to test and validate their design and process before mass production, which improves product quality and production efficiency. We’ll go over different prototyping methods in die casting.

Is Prototyping Important in Die Casting? - Benefits of Prototyping in Die Casting

Yes, prototyping is important in die casting. Prototyping allows manufacturers to test and validate their die casting process before mass production, which can help to reduce the risk of errors and defects in the final product. In die casting, a prototype is typically created using a small-scale die, which is similar in design to the final die that will be used for mass production. The prototype is used to test the die casting process and to make any necessary adjustments to the design or process before the final die is created.

Some of the benefits of prototyping in die casting include:

– Validating the design: Prototyping allows manufacturers to test the functionality and fit of the product design before mass production, which can help to identify and address any issues early in the process.

– Testing the process: Prototyping allows manufacturers to test the die casting process itself, which can help to identify any issues with the process before mass production. This can help to improve the efficiency and quality of the process and reduce the risk of errors and defects.

– Saving time and money: By identifying and addressing issues early in the process, prototyping can help to save time and money by reducing the need for rework and correcting errors during mass production.

What Are Prototyping Methods for Die Casting

There are several prototyping methods that can be used in die casting, depending on the specific requirements of the project. Here are some of the most common prototyping methods used in die casting:

– CNC machining: CNC machining is a process in which a computer-controlled machine tool is used to create a prototype from a solid block of material. This method is often used for complex geometries or parts with tight tolerances.

– 3D printing: 3D printing, also known as additive manufacturing, is a process in which a digital model is used to create a physical part by adding layers of material. This method is often used for low-volume or custom parts, as well as for creating molds for die casting.

– Rapid tooling: Rapid tooling is a process in which a tool is created quickly and cost-effectively using various methods, such as CNC machining or 3D printing. This method is often used for prototyping, as well as for low-volume production runs.

– Investment casting: Investment casting is a process in which a wax or plastic pattern is created from a 3D model and then coated in a ceramic shell. The wax or plastic is then melted out, leaving a cavity that is filled with molten metal. This method is often used for creating complex or high-precision parts.

– Sand casting: Sand casting is a process in which a mold is created by packing sand around a pattern, which is then removed to create a cavity that is filled with molten metal. This method is often used for creating large, simple parts or for producing low-volume runs.

What Are Prototyping Dies in Die Casting

Prototyping dies in the die casting are specialized tools used to create prototype parts and test the die casting process before mass production. These dies are typically smaller and less complex than production dies and are used to create a limited number of prototype parts for testing and validation purposes. Prototyping dies are made from various materials, including steel, aluminum, and plastic. They are designed to be less expensive and faster to produce than production dies, allowing manufacturers to test and validate their die casting process more efficiently.

The process of creating a prototype die typically involves several steps, including:

– Design: The design for the prototype die is created based on the product design and specifications, and may include features such as cooling channels, ejector pins, and gating systems.

– Tooling: The tooling for the prototype die is created using computer-aided design (CAD) software and may be produced using various methods, including CNC machining and 3D printing.

– Die casting: The prototype die is used to create a limited number of prototype parts using the die casting process.

– Testing and validation: The prototype parts are tested and evaluated for quality and functionality, and any necessary adjustments are made to the die design or process.

Prototyping dies is an important part of the die casting process, as they allow manufacturers to test and validate their process before committing to mass production. This can help to reduce the risk of errors and defects in the final product and improve the efficiency of the die casting process.