Difference Between Gravity and Pressure Die Casting - What is Gravity Casting | Diecasting-mould

The casting technologies of alloy can be divided into pressure die casting and gravity casting. This article will analyze the features of the two casting processes in detail and the difference between gravity casting and pressure casting.

What is Gravity Casting?

Casting can also be divided into gravity casting and pressure casting according to the pouring process of liquid metal. Gravity casting refers to the process that molten metal is injected into the mold under the gravity of the earth, also known as casting. In the broad sense, gravity casting includes sand casting, metal casting, investment casting, clay casting, etc.; in the narrow sense, gravity casting refers to metal casting.

The liquid aluminum in gravity casting is usually poured into the gate by hand. Depending on the self-weight of the liquid metal, it fills the mold cavity, exhausts, cools, and opens the mold to get the sample. The gravity casting process flow is generally: molten aluminum smelting, pouring material filling, exhausting, cooling, opening the mold, clearing production, heat treatment, and processing.

Advantages of Gravity Casting

1. There are few pores in aluminum casting, so it can be heat treated.

2. The cost of the mold is low and the service life of the mould is long.

3. The process is simple and suitable for mass production.

4. Special aluminum alloy with low fluidity can be used.

5. Materials are widely used.

Disadvantages of Gravity Casting

1. The surface finish of the product is not high, and it is easy to produce pits after shot blasting.

2. The low production efficiency increases the production cost.

3. The process is simple and not suitable for thin-walled parts.

What is Pressure Casting?

Pressure casting is a process in which liquid metal is injected into the mold under the action of other external forces (excluding gravity). The broad sense of pressure casting includes pressure casting of die casting machine, vacuum casting, low-pressure casting, centrifugal casting, etc.; the narrow sense of pressure casting specifically refers to metal pressure casting of die casting machine, referred to as die casting. These kinds of casting processes are the most commonly used and the lowest price in nonferrous metal casting.

Pressure casting is divided into high-pressure casting and low-pressure casting. High pressure casting is a casting method in which molten alloy is poured into the pressure chamber to fill the cavity of steel mould with high speed and solidify the molten alloy under pressure. The main characteristics of high-pressure die casting are high pressure and high speed.

Features of High Pressure Casting

1. Rapid prototyping, high production efficiency

2. Under high-pressure molding, the product has high density, high strength and surface hardness, and low elongation

3. The surface finish of the product is high, generally up to Ra6.3

4. It can produce thin-wall parts

5. Filling block, internal gas involved in more, product porosity is poor

6. Can’t be heat treated, the internal gas will expand during heat treatment, leading to product bulge or cracking and other defects

7. Small machining allowance, too much machining will damage the surface dense layer, internal pores exposed, resulting in the reduction of product strength

8. High cost of mould

Features of Low Pressure Casting

1.The utilization rate of casting is very high. There is no riser and runner, the gate is small, so the material cost and processing time can be greatly reduced.

2.Get the perfect casting. It is easy to form directional solidification with few internal defects.

3.Gas and debris are less involved. The pressure speed can be changed, and the molten soup is filled by laminar flow.

4.Sand cores can be used.

5.It is easy to realize automation, and can work in multiple machines and processes.

6.It is not affected by the operator’s proficiency.

7.Materials are widely used.

Difference Between Gravity and Pressure Die Casting - Gravity Casting vs Pressure Casting

1. The principle of Gravity casting is to rely on the role of gravity, so that the liquid aluminum is naturally filled into the mold by gravity. Of course, centrifugal casting is also used, which also belongs to the scope of gravity casting; The principle of die casting is to pour liquid aluminum into the injection chamber by mechanical force, such as an injection rod. The pressure is formed by the linear movement of the injection rod and injection head, forcing liquid aluminum to fill the mold;

2. Gravity casting is generally used for parts with complex internal shape (such as gasoline refueling gun), while die casting is generally used for parts with complex external shape but the simple internal shape (such as the gearbox, etc.)

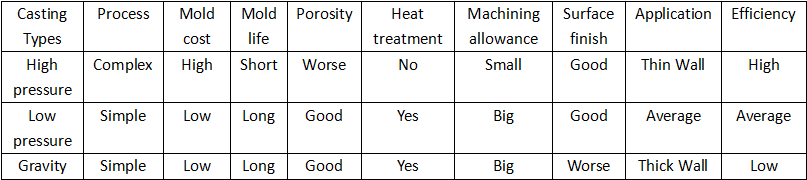

3. Comparison between gravity and pressure die casting