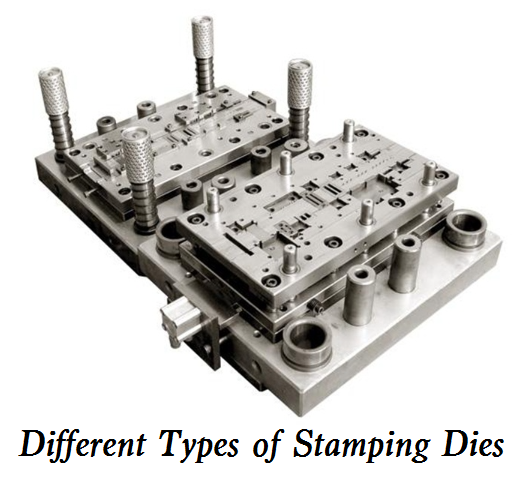

A stamping die is a tool used to produce metal parts. Here we’ll go over different types of stamping dies and products made from that.

What Is Stamping Die?

A stamping die is a specialized tool used in manufacturing to cut, shape, or mold metal or other materials. It is typically made of hardened steel and uses a combination of punches, dies, and other cutting or forming elements to create the desired shape or design. Stamping dies are often used in high-volume production processes like automotive manufacturing, appliance construction, or electronics assembly.

Different Types of Metal Stamping Dies

Types of stamping dies are classified based on their specific design, operation, and intended purpose, and they can vary widely depending on the application and industry.

– Progressive stamping dies: these dies use a single continuous feed of material that passes through a series of stations, each station performing one or more operations on the material. Progressive dies are used for high-volume production of parts that require multiple operations, such as punching, forming, and cutting.

– Transfer stamping dies: these dies use a mechanical transfer system to move the material from one station to another. Transfer dies are used for more complex parts that require several operations and intermediate steps between stations.

– Simple stamping dies: these dies perform only one operation, such as blanking, piercing, or bending.

– Compound stamping dies: these dies perform multiple operations on the material within a single die, with each station performing a different operation.

– Combination stamping dies: these dies are a hybrid of progressive and transfer dies, using a mechanical transfer system to move the material between some stations, while other stations follow a continuous feed process.

What Are Multi-Station Stamping Dies and Single-Station Stamping Dies?

Multi-station stamping dies, also known as multiple-station dies, are specialized tools used in metal forming or stamping processes. These dies have multiple stations or work stations, each with a specific function or operation, such as blanking, piercing, forming, or cutting. In multi-station stamping, the material is fed through the die, with each station performing a specific operation on the material as it moves through the die. Multi-station stamping dies are commonly used in high-volume production processes where high precision and accuracy are required, such as in the fabrication of automotive components, electronics components, and other metal parts. The two main types of multi-station stamping dies are progressive stamping dies and transfer stamping dies, but there are also other types, such as compound dies, combination dies, and more. Multi-station stamping dies enable efficient and cost-effective manufacturing of parts with consistent quality and precise dimensions.

Single-station stamping dies, also known as single-stage dies, are tools used for metal stamping or forming processes that involve only one station or operation. Unlike multi-station dies that can perform multiple operations on a part as it moves through various workstations, single-station dies are designed to perform only one operation, such as cutting, piercing, or bending. Single-station dies are typically used for small batch or low volume productions, where the volume of specific parts required is not large enough to justify the use of a multi-station die. They are more economical to make and maintain than multi-station dies but are less efficient and slower in production rate. Single-station dies are commonly used in industries such as metal fabrication, construction, and home appliance production, as well as in prototyping. They can be made from a variety of materials, such as hardened steel, carbides, or ceramics, depending on the requirements of the production process.

Stamping Dies (Die Stamped) Products

Stamping dies allow for the high-volume, efficient production of parts with consistent quality and precise dimensions, making them an essential tool in many manufacturing industries.

– Automotive parts such as panels, brackets, and reinforcements.

– Electronic components such as connector pins, lead frames, and contact springs.

– Household appliances such as metal enclosures, cookware, and utensils.

– Medical devices such as surgical instruments, implants, and diagnostic equipment components.

– Aerospace parts such as brackets, frames, and panels.

– Construction components such as brackets, connectors, and supports.

– Office equipment such as paper clips, staples, and binder rings.

– Consumer goods such as jewelry, decorative metalwork, and hardware.