Die casting is a manufacturing process in which molten metal is poured into a mold and then cooled to form a solid part. Die casting is commonly used for producing parts for a variety of industries, such as automotive, electronics, and toys. When it comes to the cost of die casting, what factors influence it and how to reduce the cost?

Factors Affecting Casting Cost

The cost of casting refers to the total expenses associated with producing a cast product, including materials, labor, and equipment. Some of the factors that contribute to the cost of casting include:

– Type of metal or alloy used

– The complexity of the part design

– Size and weight of the part

– Quantity of parts to be produced

– Production process (e.g. sand casting, die casting, etc.)

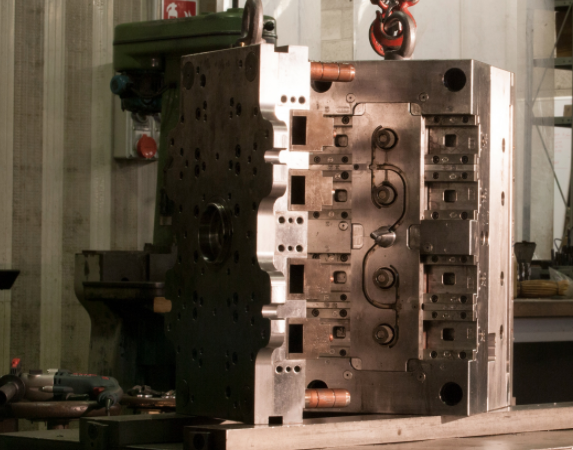

– Tooling costs (for creating the mold)

– Labor costs (for operating the casting equipment and finishing the parts)

– The cost of casting can vary widely depending on these and other factors, but it is often one of the most important considerations in the manufacturing process. To minimize casting costs, companies may use cost-saving techniques such as casting simulation, optimized part design, and high-volume production runs.

In general, aluminum is often considered to be a more expensive material compared to zinc in terms of die casting. This is due to the higher cost of aluminum raw materials and the greater difficulty in casting aluminum compared to zinc. However, zinc is often more brittle and has a lower melting point compared to aluminum, which can impact product quality and make zinc more difficult to cast for some applications. The cost of casting can also vary depending on the specific production process used. For example, die casting is typically more expensive than sand casting, but it allows for higher production speeds and improved part accuracy.

How to Reduce the Cost of Casting?

There are several ways to reduce the cost of casting, some of which include:

1) Simplifying the part design: A simpler design requires less material and less time to produce, reducing overall costs.

2) Using cost-effective materials: Choosing a lower-cost metal or alloy can significantly reduce the cost of casting.

3) Optimizing the casting process: Improving process efficiency through techniques such as process simulation and process optimization can reduce costs.

4) Reducing scrap rate: Implementing quality control measures to minimize waste and reduce scrap rates can reduce costs.

5) High-volume production: By producing a large number of parts at once, the cost per unit can be reduced through economies of scale.

6) Reusing molds: Reusing molds multiple times can reduce the cost of tooling and increase production efficiency.

7) Outsourcing to a lower-cost supplier: If feasible, outsourcing the casting process to a supplier in a lower-cost region can also reduce costs.

8) Implementing cost-saving technology: Using modern equipment and technology, such as 3D printing for prototyping and simulation software for process optimization, can reduce costs.

It’s important to consider the trade-offs between cost reduction and product quality, as some cost-saving measures may impact product quality. A balanced approach that considers both cost and quality is often the best solution.