Choosing the right knife steel can make all the difference between a reliable, razor-sharp blade and one that dulls or rusts with minimal use. With so many options available, from powder metallurgy marvels to ultra-tough tool steels, it’s essential to understand what each type brings to the table. Read our knife steels ranking 2025, we have ranked the top 10 best steels for knives.

Best Knife Steels 2025 – Top 10 Toughest Knife Steels Ranked 2025

Knife steel refers to the type of metal alloy used to make a knife blade. The composition and treatment of the steel determine the blade’s performance, including its hardness, toughness, edge retention, corrosion resistance, wear resistance, and ease of sharpening. Different knife steels are formulated to excel in specific areas, making some better suited for tasks like everyday carry (EDC), outdoor survival, or culinary use. Whether you’re an outdoor enthusiast, a professional chef, or a dedicated knife collector, knowing the strengths and weaknesses of various steel types helps you make an informed decision. Without further ado, let’s dive into the knife steel rankings, check the best knife steel chart.

What are Common Knife Steel Types?

- Stainless Steels

Stainless steels contain at least 13% chromium, making them highly resistant to rust and corrosion. They are popular for everyday carry (EDC) knives, kitchen knives, and outdoor tools.

440C: Good edge retention and corrosion resistance, but relatively brittle.

AUS-8: Medium hardness, good corrosion resistance, and easy to sharpen.

VG-10: High carbon content, excellent edge retention, and good toughness.

S30V: Premium steel with excellent edge retention and corrosion resistance.

S35VN: Improved version of S30V with better toughness and easier sharpening. - Carbon Steels

Carbon steels lack the chromium content to be considered stainless, but they are known for superior toughness and ease of sharpening. However, they are prone to rust without proper maintenance.

1095: Very tough and easy to sharpen but rusts easily.

5160: Excellent toughness, often used for large blades and swords.

52100: High carbon content with excellent edge retention, but prone to corrosion.

W2: Known for extreme sharpness and toughness, often used in custom knives. - Tool Steels

These steels are designed for durability and wear resistance, making them suitable for hard-use knives and industrial applications.

D2: Semi-stainless with high wear resistance and good edge retention.

O1: High carbon tool steel known for toughness and ease of sharpening.

A2: Tougher than D2, with moderate wear resistance and good edge stability.

M4: High-speed steel with outstanding edge retention but low corrosion resistance. - Powder Metallurgy Steels (PM Steels)

These are premium steels made through a powdered metal process, resulting in a fine and uniform grain structure. They offer an exceptional balance of hardness, toughness, and corrosion resistance.

CPM-S35VN: An upgrade to S30V, offering better toughness and slightly easier sharpening.

CPM-20CV: Excellent edge retention and corrosion resistance, similar to M390.

CPM-M4: Exceptional edge retention and toughness but prone to corrosion.

Elmax: High wear resistance and good corrosion resistance, popular in high-end knives. - High-Speed Steels

These steels are designed for cutting tools that need to withstand high temperatures and heavy use. They are often used in industrial and heavy-duty applications.

M2: Excellent toughness and edge retention but not corrosion-resistant.

T15: Outstanding wear resistance and hardness, but low corrosion resistance. - Damascus Steel

Damascus steel is known for its beautiful, wavy patterns and combines two or more steel types through forge welding. Modern Damascus usually combines high-carbon and stainless steels to achieve both aesthetic appeal and performance. - Super Steels

These are the top-tier steels that offer superior edge retention, wear resistance, and corrosion resistance, often used in premium and custom knives.

ZDP-189: Extremely hard (up to 67 HRC) with excellent edge retention but prone to chipping.

S90V and S110V: Unmatched edge retention, but difficult to sharpen.

M390: Excellent all-around performance, combining hardness, toughness, and corrosion resistance.

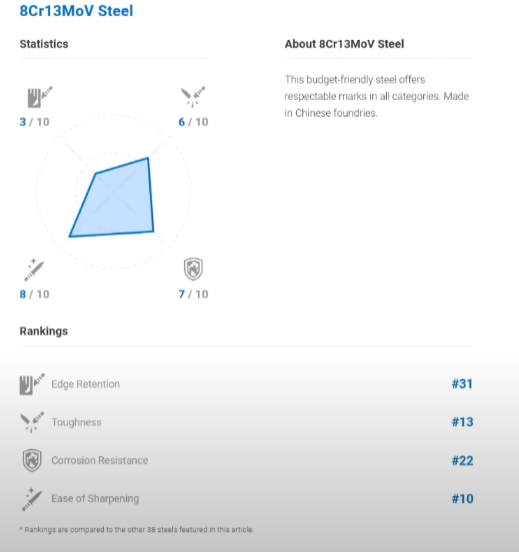

What are the Key Properties of Knife Steel?

Hardness

Hardness in knife steel refers to its ability to resist deformation when subjected to stress, typically measured on the Rockwell Hardness Scale (HRC). A higher hardness rating means the blade can maintain a sharper edge for longer periods, but it also makes the steel more brittle and prone to chipping under heavy impact. Hard steels, such as D2 and CPM-S30V, are preferred for tasks requiring fine, precise cuts but may be less suitable for heavy-duty applications where toughness is crucial.

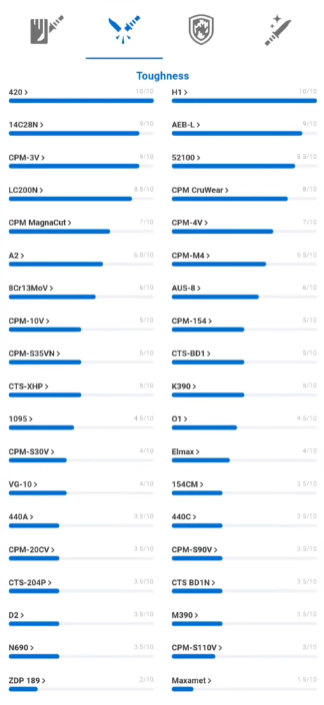

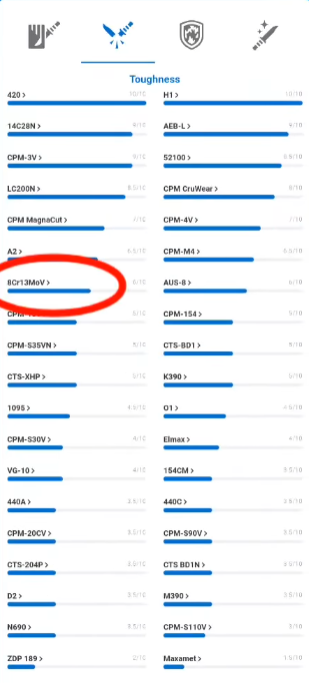

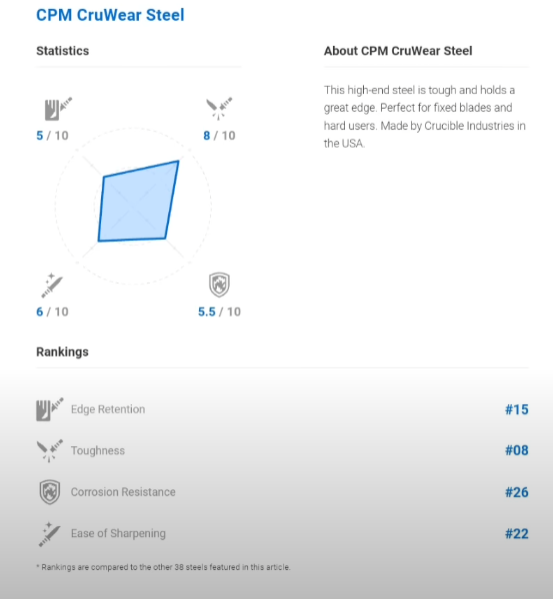

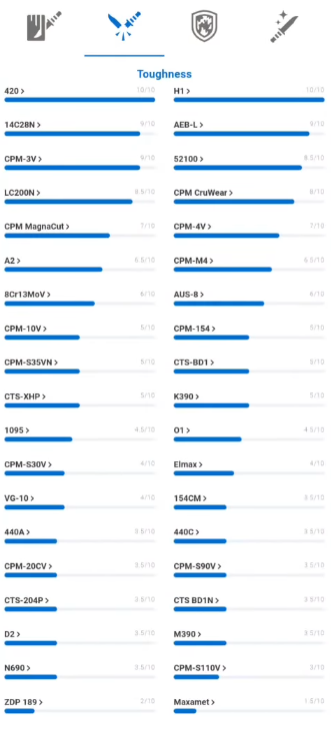

Toughness

Toughness is the steel’s ability to withstand impacts without cracking, chipping, or breaking. It is essential for knives used in demanding tasks like chopping, batoning, or prying, where the blade may encounter significant force. Toughness often has an inverse relationship with hardness, as extremely hard steels tend to be more brittle. Steels like 5160 and A2 are known for their exceptional toughness, making them suitable for survival and outdoor knives.

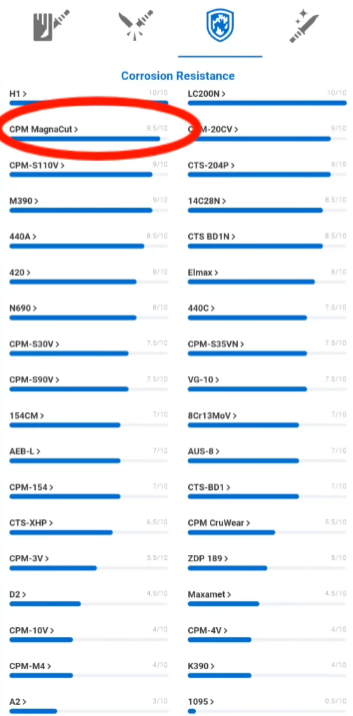

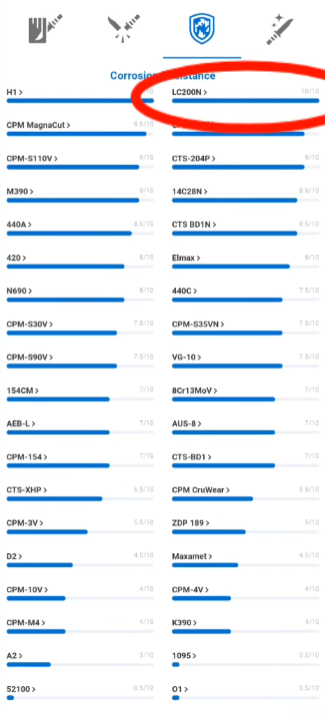

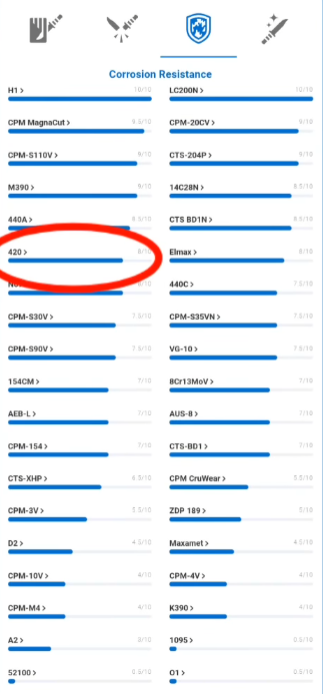

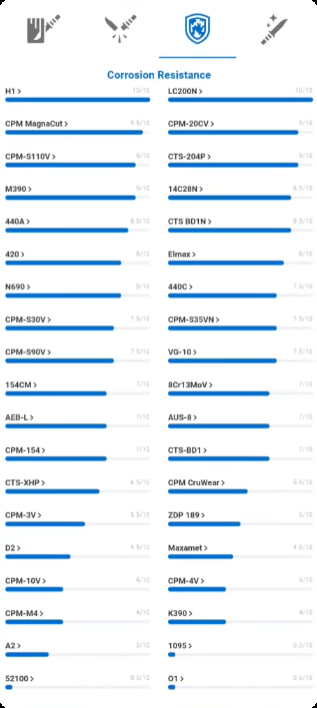

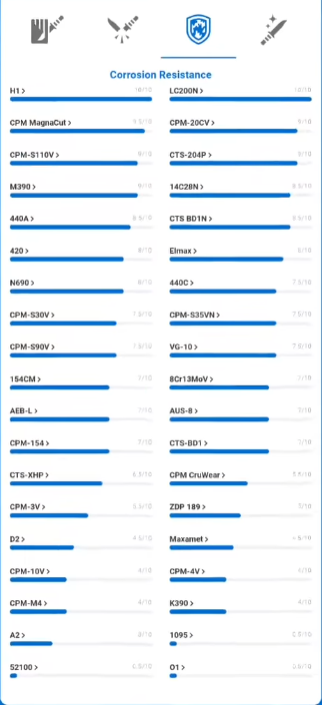

Corrosion Resistance

Corrosion resistance determines how well the steel resists rust and oxidation, which is crucial for knives exposed to moisture, humidity, or acidic environments. Stainless steels with high chromium content (typically 13% or more) offer the best corrosion resistance, while non-stainless steels are more susceptible to rust if not properly maintained. Steels like 440C and N690 excel in corrosion resistance, making them ideal for kitchen knives and outdoor tools.

Wear Resistance

Wear resistance indicates how well the knife withstands abrasion and material loss, which affects how long the blade maintains its shape and cutting performance. Steels that are highly wear-resistant, such as CPM 10V and D2, often contain hard carbides that enhance durability. While great for prolonged use without significant dulling, high wear resistance can make the blade harder to sharpen when it eventually loses its edge.

Sharpenability

Sharpenability refers to how easy it is to restore a knife’s edge, which can vary greatly depending on the hardness and carbide content of the steel. Softer steels, like 420HC and AUS-8, are relatively easy to sharpen and can be quickly honed to a razor edge. In contrast, ultra-hard steels, while maintaining sharpness longer, are often challenging to resharpen without specialized equipment or advanced sharpening skills.

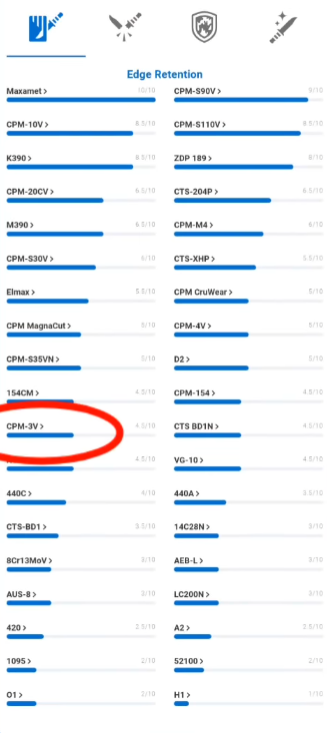

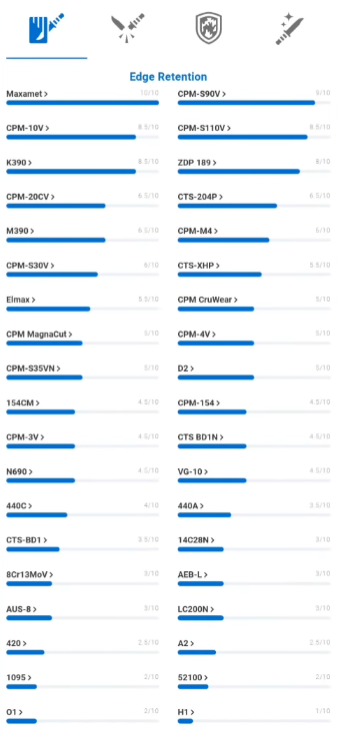

Edge Retention

Edge retention is a measure of how well a knife maintains its sharpness during use, which is critical for long-lasting cutting performance. It largely depends on the steel’s hardness, carbon content, and the presence of hard carbides like vanadium and chromium. Steels such as S90V and M390 are prized for their superior edge retention, making them popular in high-end and professional-grade knives. However, better edge retention usually means the steel is harder to sharpen.

Top 10 Best Knife Steel Ranked

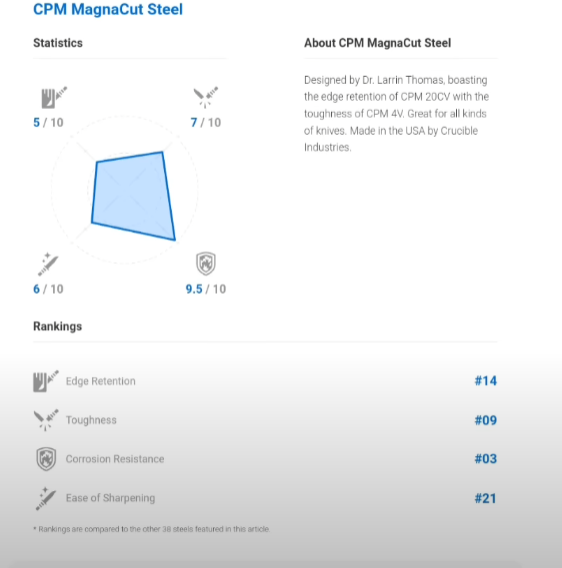

🥇 1. MagnaCut

Category: Powder Metallurgy Stainless Steel

Hardness: 61-63 HRC

Key Features: Exceptional balance of toughness, edge retention, and corrosion resistance

MagnaCut is one of the best knife steels 2025 and has taken the knife community by storm due to its near-perfect balance of qualities. Developed by metallurgist Larrin Thomas, it combines the edge retention of steels like S35VN with the toughness of steels like CPM 4V, while also offering excellent corrosion resistance. It is ideal for both EDC knives and high-performance outdoor blades.

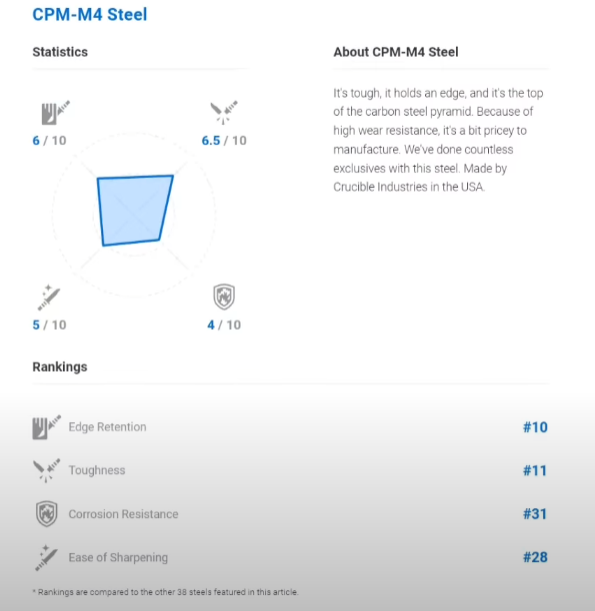

🥈 2. Spyderco M4

Category: Tool Steel

Hardness: 63-65 HRC

Key Features: Extreme edge retention and toughness, but low corrosion resistance

Spyderco’s CPM M4 is the second best steel for hunting knife 2025 known for its insane sharpness and lasting edge retention. It’s a non-stainless tool steel, meaning it requires maintenance to prevent rust, but it excels in hard-use tasks like bushcraft and heavy-duty cutting. Its high hardness makes it great for high-wear applications.

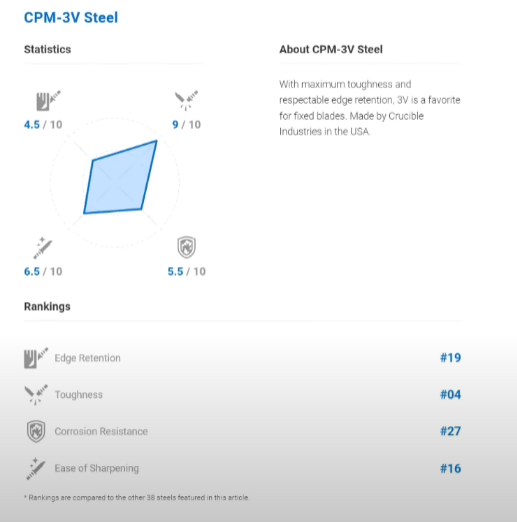

🥉 3. CPM 3V

Category: Tool Steel

Hardness: 58-60 HRC

Key Features: Outstanding toughness with good edge retention

CPM 3V is the toughest knife steels 2025 renowned for its incredible toughness while still maintaining decent edge retention. It’s the best knife steel chart for outdoor and survival knives that undergo hard use, like chopping and batoning. Although it’s not stainless, a proper coating or regular maintenance keeps rust at bay.

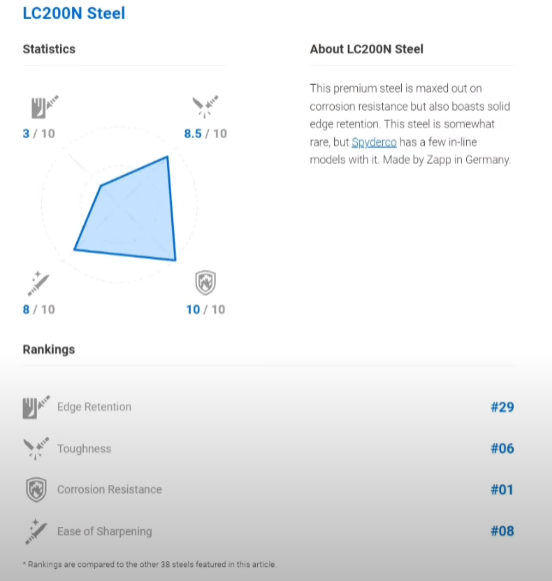

4. LC200N

Category: Nitrogen-Based Stainless Steel

Hardness: 58-60 HRC

Key Features: Unmatched corrosion resistance and good toughness

LC200N is the go-to steel for saltwater environments, as it’s virtually rust-proof. It holds an edge well and is surprisingly tough for stainless steel, making it a favorite for dive knives and outdoor tools.

5. Nitro V

Category: Stainless Steel

Hardness: 58-62 HRC

Key Features: High toughness, good edge retention, excellent corrosion resistance

Nitro V is a modified AEB-L steel, offering a good balance of edge retention and toughness, with added nitrogen for improved corrosion resistance. It’s easy to sharpen and is one of the best folding steel knife for both kitchen and EDC knives.

6. CPM 420HC

Category: Stainless Steel

Hardness: 56-59 HRC

Excellent corrosion resistance, easy to sharpen

A reliable budget-friendly steel, 420HC is commonly used in affordable knives and outdoor blades. It doesn’t have the best edge retention, but it’s highly corrosion-resistant and can be honed to a razor-sharp edge with minimal effort.

7. 14C28N

Category: Stainless Steel

Hardness: 58-60 HRC

Key Features: Good balance of corrosion resistance, edge retention, and toughness

Developed by Sandvik, 14C28N is known for being a well-rounded steel at an affordable price. It takes a very sharp edge and holds it reasonably well, while also being easy to maintain. It’s commonly used in mid-range EDC knives.

8. CPM S35VN (Ford)

Category: Powder Metallurgy Stainless Steel

Hardness: 58-61 HRC

Key Features: Excellent edge retention, good toughness, and corrosion resistance

S35VN remains a staple in premium knives due to its excellent balance of qualities. It is a refinement over S30V with improved toughness and ease of sharpening, making it a versatile choice for high-end folders and fixed blades.

9. Kware

Category: Proprietary High-Carbon Stainless Steel

Hardness: 60-62 HRC

Excellent edge retention and decent corrosion resistance

Kware steel has recently gained popularity for offering premium edge retention with good rust resistance. Its specific alloy composition is proprietary, but it’s used by some high-end knife manufacturers for its durability and sharpness.

10. Z-FiNit (ZFF)

Category: Nitrogen-Based Stainless Steel

Hardness: 58-61 HRC

Key Features: Outstanding corrosion resistance and decent toughness

Z-FiNit is another nitrogen-enhanced steel that is practically immune to rust, making it perfect for marine and fishing knives. While it doesn’t hold an edge as well as super steels, it excels in durability and saltwater resistance.