There are many types of metal plastic mold steel, and the hardness of each type is not the same. The following are some common metal and plastic mold steels and their hardness ranges:

-LKM H13: Usually the hardness range is 42-52 HRC (Rockwell Hardness).

-LKM 2344 H13: Usually the hardness range is 48-52 HRC.

-LKM4140 P20: Usually the hardness range is 28-32 HRC.

-LKM 2311 P20: Usually the hardness range is 28-32 HRC.

-S136H: Usually the hardness range is 48-52 HRC.

-S136: Usually the hardness range is 48-52 HRC.

-718H: Usually the hardness range is 30-36 HRC.

– NAK80: Usually the hardness range is 37-43 HRC.

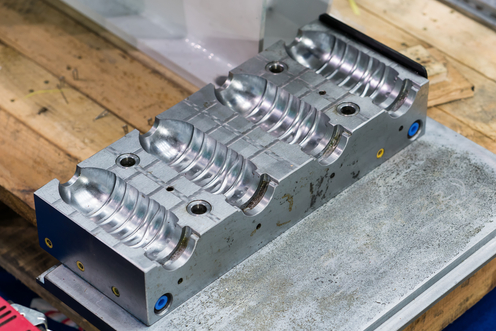

Metal Plastic Mold Steel Definition, Structure, Application Field

1. LKM H13 and LKM 2344 H13: They both belong to H13 steel and have similar steel structure. H13 steel is a hot tool steel mainly composed of elements such as carbon, silicon, manganese, molybdenum, chromium, and cobalt. It has high hardness, excellent heat resistance, and wear resistance, and is suitable for manufacturing high-demand plastic molds, die-casting molds and hot-pressing molds, etc. In real life, H13 steel is often used in the manufacture of molds for auto parts, home appliance casings, and electronic product casings.

2. LKM4140 P20 and LKM 2311 P20: They both belong to P20 steel and have similar steel structure. P20 steel is a low carbon steel mainly composed of elements such as carbon, silicon, manganese and chromium. It has good cutting performance, excellent machinability and corrosion resistance, and is suitable for making plastic molds and die-casting molds with medium requirements. In real life, P20 steel is often used in the manufacture of molds for plastic containers, toys, household items, etc.

3. S136H and S136: They both belong to S136 steel and have similar steel structure. S136 steel is a stainless steel mainly composed of elements such as carbon, silicon, manganese, chromium, nickel and molybdenum. It has excellent corrosion resistance, high hardness and good polishing performance, and is suitable for manufacturing plastic molds, optical molds and medical device molds that require high precision and high finish. In real life, S136 steel is often used in the mold manufacturing of mobile phone casings, glasses frames, medical equipment, etc.

4. 718H: 718H is a special pre-hardened steel with high hardness and toughness. It is suitable for making large plastic molds and die-casting molds, and has excellent wear resistance and high temperature performance. In real life, 718H is often used in the manufacture of large molds such as automotive interior parts and home appliance casings.

5. NAK80: NAK80 is a special plastic mold steel with high hardness and high toughness, mainly composed of carbon, silicon, manganese, chromium, nickel and molybdenum. It has excellent machinability and heat resistance, and is suitable for manufacturing plastic molds that require high precision and high surface quality. In real life, NAK80 is often used in the mold manufacturing of optical lenses, mobile phone keyboards, electronic product casings, etc.

Common Hardware Plastic Mold Steel Brand Manufacturers

Below are some steel suppliers and brands with a good reputation in the mold industry:

-LKM (Lung Kee Group): This is a mold manufacturer and supplier in Hong Kong, offering a variety of mold steels, including H13, 2344 H13, 4140 P20, and 2311 P20, etc.

-ASSAB (Assab Group): This is one of the world’s leading mold steel suppliers, offering various mold steels such as S136H, S136, 718H and NAK80 P21 etc.

-Finkl Steel: Finkl Steel (now Schmolz + Bickenbach) is an American mold steel supplier, providing high quality mold steel, including H13 and P20 etc.

-Daido Steel: Daido Steel is a Japanese die steel supplier that offers a wide range of die steels, including H13, P20, and NAK80, among others.

| Die Steel | Price (USD/ton) |

| LKM H13 | 278 – 309 |

| LKM 2344 H13 | 294 – 325 |

| LKM 4140 P20 | 247 – 278 |

| LKM 2311 P20 | 232 – 263 |

| S136H、S136 | 340 – 371 |

| 718H | 263 – 294 |

| NAK80 | 309 – 340 |

| P21 | 247 – 278 |

What Are the Common Welding Methods for Mold Steel

Manual arc welding, argon arc welding, gas shielded welding, and laser welding are suitable for thicker mold steel. In addition to manual arc welding and argon arc welding, there are other common methods of welding mold steel, including the following:

1. Manual arc welding: Manual arc welding is suitable for mold steels of various thicknesses, from thin plates to thicker plates. By selecting the appropriate welding current, electrode diameter and welding technique, it can be adapted to different thicknesses of mold steel.

2. Argon arc welding: Argon arc welding is suitable for thinner mold steel, generally suitable for steel thickness range from 1mm to 10mm. TIG welding provides low heat input and small heat-affected zone, suitable for fine welding of thin plates.

3. Gas shielded welding (GMAW/MIG welding): Gas shielded welding is suitable for thicker mold steel, generally suitable for steel thickness above 3mm. Gas shielded welding provides high melting rate and high welding speed, suitable for fast welding of thicker mold steel.

4. Laser welding: Laser welding is suitable for mold steels of various thicknesses, and laser welding can be performed from thin plates to thicker plates. Laser welding has the characteristics of high energy density and small heat-affected zone, and is suitable for fine welding of thin plates and molds with complex shapes.

5. Soldering: Soldering uses solder as the welding material, melts it by heating the solder, and connects it to the mold steel. Solder welding is often used for the connection of smaller mold parts, such as the assembly of electronic molds.

6. Welding stud (Stud Welding): Welding stud is a special welding method used to weld the stud to the surface of the mold steel to facilitate the fixing of accessories or other components. Weld studs provide a secure connection and can be replaced or adjusted as needed.

Which Mold Steel Welding Method Is Suitable for Metal Plastic Mold Steel

When selecting an appropriate welding method, factors such as specific welding requirements, mold design, and operating conditions should also be considered. It is recommended to consult a professional welding engineer or mold manufacturing expert such as diecasting-mold before welding die steel to obtain the best welding advice for specific steel. The following are various common metal and plastic mold steels and their applicable welding methods:

-LKM H13: LKM H13 is a hot work tool steel suitable for tool making under high temperature and high stress environment. Common welding methods include manual arc welding, argon arc welding, and gas shielded welding (GMAW/MIG welding).

-LKM 2344 H13: LKM 2344 H13 is also a hot work die steel with high hardness and wear resistance. Applicable welding methods include shielded arc welding, argon arc welding and gas shielded welding (GMAW/MIG welding).

-LKM 4140 P20: LKM 4140 P20 is a pre-hardened plastic mold steel commonly used in plastic injection mold making. Applicable welding methods include shielded arc welding, argon arc welding and gas shielded welding (GMAW/MIG welding).

-LKM 2311 P20: LKM 2311 P20 is also a commonly used plastic mold steel for medium hardness and medium size molds. Common welding methods include manual arc welding, argon arc welding, and gas shielded welding (GMAW/MIG welding).

-S136H, S136, 718H, NAK80, and P21: These steels are all stainless or corrosion-resistant mold steels, suitable for high-precision and high-finish mold manufacturing. For these materials, common welding methods include laser welding, argon arc welding, and resistance welding, among others.