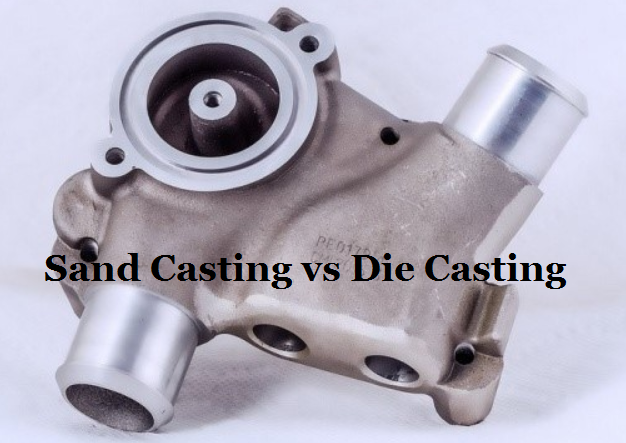

Sand Casting vs Die Casting, Which Process is More Advisable for Cast Parts? | Diecasting-mould

There are multiple casting methods available in the metal foundry industry, they are classified and named based on how the process is done and which type of mold is used. To choose the right casting process for the specific project, we should understand the basics of various casting types. In this article, we’ll introduce what is sand casting and the difference between sand casting and die casting, to find the more advisable one.

What is Sand Casting?

Sand casting, also known as sand molded casting, similar to die casting, it’s also a metal casting process in which the sand is used as the mold material. Sand casting is one of the oldest casting processes, can be traced back to earlier than 1000 B.C. It’s also probably the most versatile and widely used metal casting method, more than 60% of all metal casting parts are produced via the sand casting process.

Advantages and Disadvantages of Sand Casting

Sand casting has a wide range of adaptability, it suits small or large, simple or complex parts, single piece or large batch production. Sand mold has higher fire resistance than metal mold, so it is often used in materials with high melting points such as copper alloy and ferrous metal. However, sand casting also has some shortcomings. Because each sand mold can only be poured once, the mold will be damaged after obtaining the casting product and must be reshaped, so the production efficiency of sand casting is low; in addition, the overall property of sand is soft and porous, the dimensional accuracy of sand casting is low and the surface is rough.

Difference Between Sand Casting and Die Casting - Sand Casting vs Die Casting

Sand casting is the most traditional casting method, which uses sand to make a mold cavity for casting. However, the pressure in sand casting is often insufficient, which leads to defects such as insufficient filling and cold shut. Therefore, a new casting method has been developed: die casting, in which the fluidity and filling ability of liquid metal are enhanced by artificial pressure, and better quality castings can be obtained. The molten alloy is poured into the pressure chamber and filled with steel mold at high speed, the alloy liquid will solidify under pressure to form the die casting parts. The main characteristics of die casting which are different from other casting methods are its high pressure and high speed.

Check out the die casting and sand casting difference to figure out which process is more advisable for cast parts.

1. Mold material. The biggest difference between die casting and sand casting is the material used to make a mold. Sand casting takes sand as the main mold making material, while die casting usually uses steel to manufacture the die casting mould.

2. Application. Die casting is a more preferred solution for medical device projects, while choosing sand casting is more cost-effective when you want to manufacture furniture.

3. Products. Sand casting parts often have a thicker wall and large sand castings may be produced with less precision. Die casting can deliver precise parts with complex shapes.

4. Cost-effectiveness. Die casting is cost-effective in the long run, even though its mold made of steel cost higher in the initial stage, with time goes on, production costs will also decrease because the steel mode is can be used repeatedly.

5. Capacity. Die casting can produce features that can be achieved by sand casting.

6. Process. In sand casting, the liquid metal is poured directly into a mold in the sand and there is no high pressure involved, while die casting is a process in which the molten metal is forced into a die under high pressure.