Temperature Control Of Die Casting Mold - How Important Is Temperature In Die Casting Mold | Diecasting-Mould

Mold temperature is an important factor in die cast production. The temperature control of die casting mold refers to the use of a certain method and means to keep the temperature of the mold within a certain range in the whole die casting production process. The temperature control range is the die casting mold operating temperature. Under the suitable working temperature, the die casting mold can stably produce qualified die casting parts and maintain high production efficiency. Below guide makes an analysis to the die casting mold temperature including:

Importance of temperature in die casting mold

Impacts of die casting molds working temperature on quality of die casting parts

Selection of temperature in die casting mold

Die casting mold temperature control methods

Best Die Casting Mold Temperature Control Method

In order to ensure the normal and continuous production process of die casting, the working temperature of mold should be kept in a certain range, so the mold must be in the state of thermal balance. Mold thermal balance means that in each die casting cycle, the heat transferred from the molten metal to the mold should be equal to the heat transferred by the mold and the heat transferred by the cooling and heating devices.

What are the best die casting temperature control methods? At present, many factories choose the mold temperature machine for die casting mold temperature controlling. By controlling the fluid temperature, flow rate and other parameters in the mold temperature machine to control the mold temperature, improve the cooling rate and improve the production efficiency. The advantage of using mold temperature machine is that it can effectively shorten the casting crystallization solidification time, improve the die casting mold making efficiency, reduce the reject rate and prolong the die life.

What Is Proper Die Casting Mold Temperature

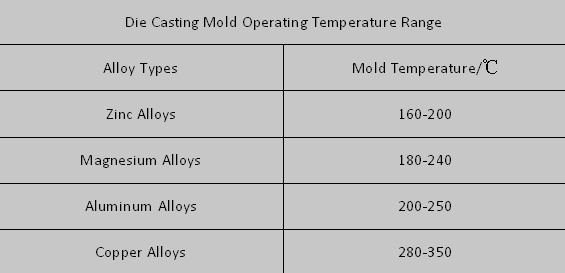

The selection of die casting mold temperature is mainly based on the shape size and structural characteristics of the die casting, the properties of alloy and pouring conditions and other factors. The preheating temperature and working temperature of common die casting molds are as follows:

In the process of mold filling, mold temperature has great influence on liquid temperature, viscosity, fluidity and filling time. When the mold temperature is too low, the surface layer is condensed and broken by high-speed liquid flow, resulting in surface defects. When the mold temperature is too high, although it is beneficial to or smooth casting surface, it is easy to appear shrinkage depression. At the same time, the mold temperature has a great impact on the mold life and die cast size, which shows the importance of temperature control in die casting mold.

What Is The Function Of Controlling Mold Temperature In Die Casting Process

1. Improve The Quality Of Die Cast

Too high or too low temperature of die casting mold will affect the quality and performance of die casting parts. First of all, when the mold temperature is too low, the following defects will appear:

● The liquid metal entering the mold cavity will rapidly reduce the fluidity, which makes the casting easy to produce cold shut, insufficient pouring, cracks, pores and unclear contour and other defects.

● The surface of mold cavity is strongly impacted by liquid metal, and the temperature difference between inside and outside the mold wall is large, and the metal mold is easy to crack and damage.

● Sometimes it will destroy the condition of sequential solidification, at this time, it is not possible to rely on coating adjustment alone. When the mold temperature is too high, the cooling rate of liquid metal in the mold is slow down, and the defects such as pinhole or shrinkage cavity are easy to appear in the die casting parts, which seriously affects the die casting parts quality. At the same time, the liquid metal is easy to stick to the mold during die casting, which leads to difficulty in demoulding, damages the surface of mold cavity and damages the die casts. Therefore, only by keeping the temperature of die casting mould within the required temperature range can get high quality die casting parts.

2. Prolong The Life Of Die Casting Mold

If the die casting mold is put into production at room temperature, in addition to failing to obtain qualified die casts, the high-temperature molten metal will have a very large thermal impact on the mold cavity after high-speed injection. The mold surface is subjected to huge instantaneous thermal shock, and the huge temperature gradient will promote the generation of thermal stress inside the mold, thus causing cracks on the mold surface. When the mold temperature is higher and higher with the increase of injection times, the thermal stress inside the mold will also be larger and larger. In addition, with the impact stress of high-speed injection, the mold will soon crack until failure, so improper temperature control of the mold will seriously reduce the service life of the mold.