Aluminum is the most widely used material for die casting due to its excellent properties. One such material is ADC6 aluminum alloy, a lightweight, high-strength alloy commonly used in industries like aviation, automobiles, and construction. In this blog, we will explore the key properties, composition, and applications of ADC6 aluminum alloy, as well as compare it to ADC12 – a similar but distinct aluminum alloy.

1. What is ADC6 Aluminum Alloy?

ADC6 is part of the Al-Mg-Mn (aluminum-magnesium-manganese) family of aluminum alloys. It is known for its high strength, good corrosion resistance, and excellent machinability. ADC6 aluminum alloy offers better castability than some other aluminum alloys, such as ADC5, but is slightly inferior in corrosion resistance when compared to ADC5. Its unique properties make it suitable for a variety of applications, ranging from motorcycle components to outboard motor propeller cases.

Common Aluminum Alloys for Die Casting

| Alloy System | Features | Main Alloys |

|---|---|---|

| Al-Si Series | Good castability | ADC1, ADC7 |

| Al-Mg Series | Excellent corrosion resistance | ADC5, ADC6 |

| Al-Si-Cu Series | High castability and strength | ADC10, ADC12 |

The ADC6 alloy falls under the Al-Mg Series, which is known for its superior corrosion resistance. This makes it suitable for various applications such as motorcycle components and marine environments.

Key Features of ADC6 Alloy Material:

- High strength: Can withstand large loads and pressures.

- Good corrosion resistance: Effective against various environmental conditions such as atmospheric and seawater exposure.

- Good thermal conductivity: Suitable for applications requiring heat dissipation.

- Machinability: Easy to process into parts of various shapes and sizes.

2. ADC6 Aluminum Chemical Composition

The performance of ADC6 aluminum alloy is largely driven by its chemical composition. Below is an overview of its key elements:

- Aluminum (Al): The primary matrix element that provides high strength and good corrosion resistance.

- Magnesium (Mg): 2.5-4.0%, Enhances the strength and toughness of the alloy.

- Silicon (Si): 9.0-11.0&, Improves thermal conductivity and corrosion resistance.

- Manganese (Mn): 0.5% or less, Helps with wear resistance and machinability.

- Iron (Fe): 0.1% or less, Must be controlled to avoid reduced strength.

- Copper (Cu): 0.1% or less, High levels can negatively impact corrosion resistance.

- Zinc (Zn): 0.1% or less, Should also be controlled to maintain performance quality.

The careful control of these impurity elements (Fe, Cu, Zn) ensures the alloy maintains its desired mechanical and thermal properties.

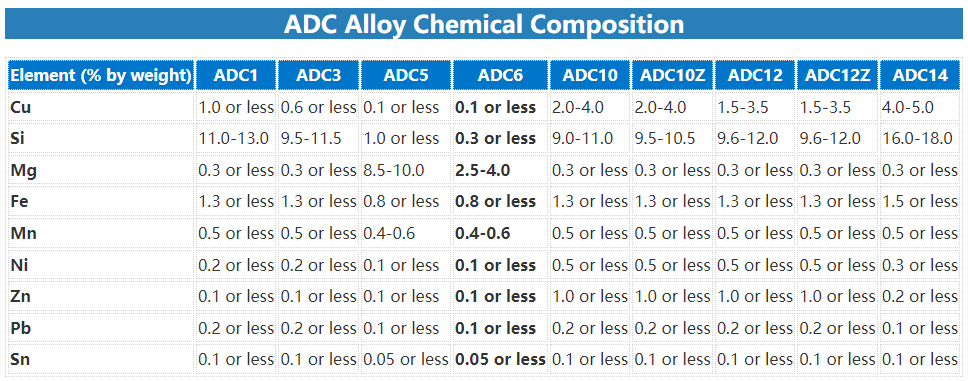

ADC Aluminum Alloy Chemical Composition Comparison

Here we list the following table to show the Chemical Composition of Aluminum Alloys for Die Casting (ADC1, ADC3, ADC5, ADC6, ADC10, ADC12, ADC14), to help you better understand their differences:

3. ADC6 Aluminum Mechanical Properties

ADC6 aluminum alloy exhibits a balance of strength, ductility, and corrosion resistance, making it ideal for a wide range of applications.

ADC6 Mechanical Properties:

- Tensile Strength: ~266 MPa

- Yield Strength: ~172 MPa

- Elongation: ~6.4%

- Brinell Hardness: ~64.7 HBS

- Rockwell Hardness: ~27.3 HRB

ADC6 Density:

- Density: ~2.68 g/cm³

ADC6 Hardness:

- Brinell Hardness: ~64.7 HBS

- Rockwell Hardness: ~27.3 HRB

ADC6 Thermal Conductivity:

- Thermal Conductivity: ADC6 has good thermal conductivity, making it suitable for applications where heat dissipation is essential.

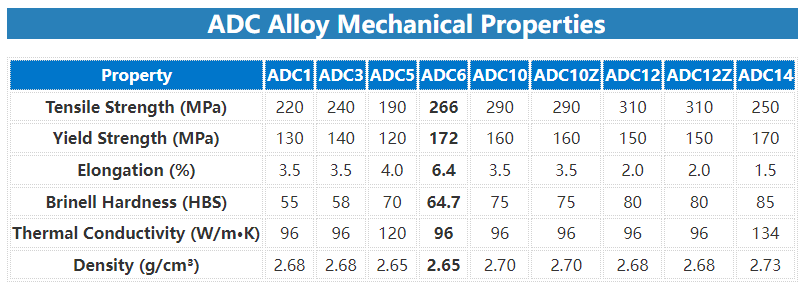

ADC Aluminum Alloy Material Properties Comparison

Here we list the following table to show the Mechanical Properties of Aluminum Alloys for Die Casting (ADC1, ADC3, ADC5, ADC6, ADC10, ADC12, ADC14), to help you better understand their differences:

4. ADC6 Aluminum Equivalent Materials

When selecting materials, it’s essential to understand the equivalent materials that can serve in similar conditions. The closest equivalents to ADC6 are:

- A356.0 (USA): This alloy is frequently used in aerospace and automotive applications due to its strength and corrosion resistance.

- EN AC-42100 (Europe): Another comparable aluminum alloy with similar mechanical and corrosion resistance properties.

5. ADC6 Material Applications (Uses)

ADC6 is widely used across various industries due to its mechanical and thermal properties. Below are some notable applications:

- Automotive: Motorcycle hand levers, water pumps, signal light holders, and outboard motor propeller cases.

- Aerospace: Aircraft components and missile casings.

- Military: Parts for military equipment and weapon components.

- Electronics: Housings and radiators where heat dissipation is required.

Its good fluidity also allows for complex mold shapes, making it ideal for high-precision castings.

6. ADC6 vs ADC12 Aluminum: What is the Difference & Which is Better?

Both ADC6 and ADC12 are aluminum alloys used for die casting, but they have distinct properties making them suitable for different applications.

Key Differences:

- Composition:

- ADC6 is an Al-Mg-Mn alloy, offering better strength and corrosion resistance.

- ADC12 is an Al-Si-Cu alloy, known for its excellent castability and high wear resistance at elevated temperatures.

- Mechanical Properties:

- ADC6: Higher tensile and yield strength, suitable for load-bearing applications.

- ADC12: Lower strength but superior wear resistance and thermal stability at high temperatures.

- Castability:

- ADC12 has better castability, making it more suitable for complex shapes and thinner sections.

- ADC6 has good castability but is slightly inferior to ADC12 in this regard.

- Corrosion Resistance:

- ADC6 has better corrosion resistance, especially in harsh environments like marine settings.

- ADC12 is more prone to corrosion if not properly coated or treated.

Which is Better?

The choice between ADC6 and ADC12 depends on the specific requirements of your application:

- Choose ADC6 if you need high strength, good corrosion resistance, and machinability. It’s ideal for applications requiring high load-bearing capacity and long-term durability.

- Choose ADC12 if your application requires better castability, wear resistance, and heat resistance at higher temperatures, especially for intricate or thin-walled components.

ADC6 aluminum alloy is a versatile and high-performing material, well-suited for use in industries requiring strong, corrosion-resistant components with good machinability. It is particularly effective in automotive, aerospace, and electronic applications. When selecting between ADC6 and ADC12, it’s important to consider the specific mechanical and environmental demands of the application.

If you are considering ADC6 for your die casting needs, it is a strong choice for applications requiring durability, precision, and corrosion resistance. However, for high-temperature environments or when cost is a concern, ADC12 might be a better fit. Contact a die-casting expert for personalized advice on material selection.