Aluminum is a lightweight alloy which possesses high dimensional stability in complex shapes and designs with thin wall sections. Aluminum can also withstand higher operating temperatures offers excellent corrosion resistance and versatility that can be utilized in many industries. Here, we are going to tell you everything you need to know about aluminum die casting and aluminum die casting process.

What Is Aluminum Die Casting?

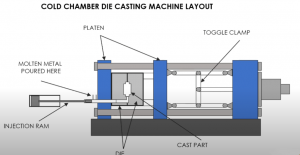

The aluminum die casting process uses the cold chamber casting machine, where the ingots are melted in a separate furnace and the molten metal is ladled from the holding pot for each casting. Because the high temperatures of molten aluminum would damage the machine if the injection mechanism were submerged as per the hot chamber process. You can clearly see here the plantens, the toggle system which closes the die, the die itself, the cast part or in this case the cavity, the injection ram system and where the molten metal is poured into.

Cold Chamber Die Casting Machine Layout

What’s The Aluminum Die Casting Process?

Step 1: Adding The Molten Aluminum

Before the die halves are shut, die lubrication or release agent is applied to the surfaces, this helps with part ejection after the casting has cooled. The die halves shut and are held together by the clamping system. The pressure of the clamping system must be greater than the force trying to open the die halves during the injection process. The pressure will depend upon the size and the complexity of the casting design. Molten aluminum is then laid out into the shock chamber ready for the injection cycle. The molten aluminum fills the shock chamber.

Step 2: The Injection Phase

The injection ram pushes the molten aluminum down the cold chamber into the die cavity. During the movement the ramp seals off the import. Pressures during the injection phase camber between 300 psi or 1.3 tonnes up to 50,000 psi which is around 22 tons, depending upon the size of the machine. Pressure is maintained while the casting is solidifying pressure can be increased during this phase to ensure the cavity is completely filled and casting integrity is achieved.

Step 3: Ejection Phase

Once the casting has caused sufficiently the die is opened. The ejector system then pushes the casting out of the die half. During this time the injection ram is retracted exposing the input port. The casting is removed than the machine, either it dropped clear or is removed by robotic arm. Die lubrication or release agent is then applied it to the die halves.

Step 4: Die Halves Close

The die halves close ready for the next cycle. Basically, they are the four steps that complete this cold chamber process.

Aluminum Product Demand Increase

China is dominant in the production of aluminum around the world. Aluminum product demand increase, so China continues to be the primary driver for growth. China has long since become the world’s largest production of aluminum, but even demand is growing there faster than anywhere else. China continues to be the primary driver of growth in the aluminum industry, and immobility is the major factor. Global demand for primary and recycled aluminum is being fueled by the trend towards lightweight construction in the automotive industry. The consumption of aluminum is growing in the booming aerospace industry, while the upturn in the construction industry in continental Europe is also stimulating demand. In addition, demand in the mechanical engineering and packaging markets continues to increase.

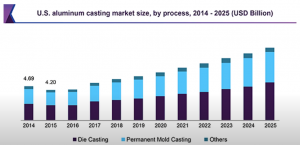

The global aluminum casting market size was estimated at 47 point 1 billion in US dollars in 2018. It is anticipated to witness a compound average growth rate of a nine point one percent from 2019 to 2025. Upswing in the use of aluminum in automobile manufacturing and heightened demand from the building and construction sector in Asia Pacific has boosted the growth of the markets. Here’s one more chart showing the U.S. aluminum casting growth from 2014 right up to 2025 as a forecast.