Pewter is a malleable metal alloy composed primarily of tin with additions of other metals like copper, antimony, bismuth, or lead. Historically, pewter was used for items like plates, tankards, candlesticks, and other household objects. Its softness made it prone to scratches and dents with use. Modern pewter alloys contain less lead for health reasons and are used more for decorative objects.

What Are the Properties of Pewter? – Physical, Mechanical, Thermal & Electrical Properties

Here are some more specific data points on the properties of pewter:

– Density: 7.3-8.7 g/cm3

– Melting point: 170-230°C, with modern lead-free pewters melting around 210-240°C

– Brinell hardness: 8-45, varies significantly based on alloy composition

– Tensile strength: 140-190 MPa

– Elongation at break: 15-70%, quite ductile

– Electrical conductivity: 7% IACS (comparable to stainless steel)

– Thermal conductivity: 50 W/mK

– Color: Grayish, precise hue varies with alloying elements

– Main alloying elements:

- Tin: 90-99%

- Copper: 0-6%

- Antimony: 0-8%

- Bismuth: 0-5%

– Historical pewter also contained: Lead: 5-35% (mostly removed today for health reasons)

What Are the Uses of Pewter?

Key properties that make it useful include its easy castability, dull gray sheen, affordability, resistance to tarnishing, and associations with history. Lead-free modern pewter makes it safe for things like jewelry and tableware. The softness still limits it from high-wear applications. But it maintains popularity for decorative objects, jewelry, and tableware. Here are some details on the uses of pewter and some well-known brands that work with it:

- – Tableware: Plates, cups, tankards, bowls, pitchers. Pewter doesn’t impart taste to food. Brands like Buckingham Pewter, and Wentworth Pewter.

- – Decorative Items: Figurines, Christmas ornaments, vases, boxes, candlesticks, trophies. Affordable material for detailed casting. Brands like Design Toscano, and Kaufmann Mercantile.

- – Jewelry: Pendants, rings, earrings, bracelets. Lead-free pewter is safe for jewelry. Brands like Pelt, Melinda Maria, Materia Bella, and Allen Designs use pewter for jewelry.

- – Miniatures: Pewter is used to make detailed miniatures like wizard figurines, soldiers, and animals. Hobby brands like Reaper Miniatures, Games Workshop, and Dungeons & Dragons use pewter.

- – Musical Instruments: Pewter can be used for parts like flutes, bagpipe chanters, and organ pipes. Mainly seen in higher-end instruments. Brands like McCallum Bagpipes, and Pearl Flutes.

- – Specialty Items: Pewter inlays, pens, buttons, souvenirs like thimbles, medallions, and goblets. A material associated with medieval/gothic/fantasy styles.

What Are the Advantages and Disadvantages of Pewter?

Pewter provides an affordable and attractive material but requires care and maintenance due to its softness. Lead-free alloys make it safer for consumers today.

Advantages:

- – Affordable

Pewter is relatively inexpensive compared to precious metals like silver or gold. This makes it accessible for makers and consumers.

- – Easy to Shape

With a low melting point and high malleability, pewter is easy to cast, mold, engrave, and shape into objects and designs.

- – Does Not Tarnish

Pewter is resistant to tarnishing and corrosion, keeping its shiny appearance over time.

- – Lead-free Varieties

Modern lead-free pewter alloys are safe for use in tableware and jewelry.

- – Distinctive Appearance

The dull, matte gray color provides a distinctive, vintage look.

Disadvantages:

- – Soft

Pewter has a low hardness and is prone to scratches, dents, and showing wear over time. Not suitable for high-use items.

- – Contains Lead

Historic pewter formulas contain lead, which is toxic. Modern lead-free versions address this.

- – Limited Strength

With a low tensile strength, pewter is unsuitable for structural applications requiring durability.

- – Deforms Easily

The softness and malleability mean pewter can bend and deform if not handled carefully.

- – Oxidation

Some pewter alloys can develop a white oxidation layer on the surface over time.

- – Limited Applications

Cannot withstand high temperatures. Mainly used decoratively or for tableware, not industrial applications.

How Is Pewter Used in the Manufacturing Process?

Key advantages for manufacturing include the ease of casting fine details, machinability, ability to accept finishes and engraving, capacity for spinning, and how it can integrate both traditional crafting and modern additive methods. These make pewter ideal for artisanal creations and small-batch productions.

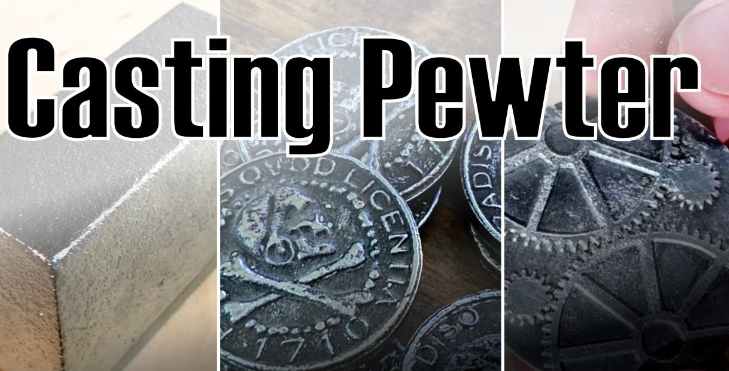

- Casting

Pewter’s low melting point makes it ideal for casting into molds. This is done through methods like permanent mold casting, sand casting, or die casting. Molten pewter easily fills intricate molds to produce detailed products. Common die-casting methods used include hot chamber die casting or cold chamber die casting.

- Machining

After casting, pewter can be machined using lathes, CNC machines, drilling, milling, etc. to achieve final dimensions and designs. Its softness makes pewter easy to machine with basic tooling.

- Spinning

The malleability of pewter allows it to be spun on a lathe into curved and ornate shapes like chalices, bowls, candlesticks. Spinning makes use of the ductility.

- Engraving & Etching

Pewter readily accepts engraved designs or etched patterns through hand-engraving or chemical etching processes. Resists wear on engraved areas.

- Joining

Soldering, welding, riveting, or adhesives can join pewter components into more complex final products. Low melting point allows soldering.

- Polishing & Finishing

A high-shine finish can be achieved by polishing and buffing. Oils or sealants applied help retain luster. Give unique finishes.

- Additive Manufacturing

3D printing methods like selective laser sintering can directly print detailed pewter pieces from a digital model.