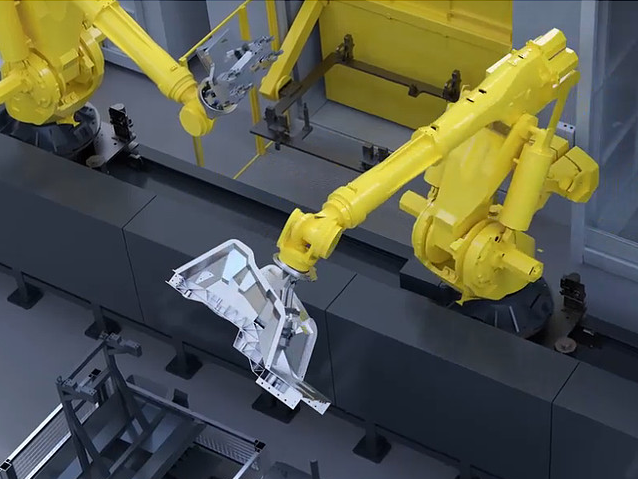

JUNYING’s magnesium die casting manufacturing capabilities are built on a foundation of innovation and efficiency. From material research and development, product design, mold design, precision casting, and machining to surface treatment, we ensure every step of the magnesium die casting process is executed flawlessly, providing one-stop lightweight and high-performance component manufacturing solutions for various industries. JUNYING’s extensive experience in the die casting field enables us to handle complex projects with precision and attention to detail, focusing on the research, production, and sales of lightweight high-pressure magnesium alloy die casting products. Our high-quality magnesium alloy die cast parts and products are used in new energy vehicles, electronic 3C products, rail transit, 5G communication equipment, and the low-altitude economy. Our advanced die casting processes and strict quality control measures ensure the consistent delivery of first-class products.

Magnesium alloy die casting is a high-pressure, high-speed forming method that integrates the die casting machine, mold, and alloy as a unified system. The process closely couples pressure, speed, and timing to achieve stable and precise replication of castings. Compared to aluminum alloy die casting, magnesium alloys have a lower heat capacity, and their filling and solidification processes are more rapid. This places higher demands on the energy reserve of the die casting machine, the filling speed, and the stability of temperature control. To ensure safety and material efficiency, the melting and pouring stages are usually equipped with dedicated furnaces that use protective gases to effectively isolate the surface of the melt pool, enabling precise metered pouring and consistent temperature control.

Magnesium alloys have a relatively low melting point, and their density, specific heat, and latent heat of solidification are all lower than those of aluminum alloys. During the melting and die casting process, they do not react with iron, resulting in lower energy consumption for melting and faster solidification – typically shortening the injection cycle by about 20% to 30%. In terms of mold life, magnesium alloy die casting molds can usually reach over 200,000 cycles, with some cases reported to reach the million level. It should be noted that molten magnesium is highly prone to oxidation and combustion, and its sensitivity to hot cracking is higher than that of aluminum alloys, which makes the processes of melting, pouring, and mold temperature control more complex.

SThe first step in magnesium die casting is mold design. The quality of the mold design directly affects the forming and performance of the final part. Our engineers carefully consider the structural features of the part, forming process, and material flow to ensure the highest product quality.

Based on the specific requirements of each part and the characteristics of the selected magnesium alloy, we set appropriate die casting parameters—including injection speed, injection pressure, and mold temperature. Proper parameter settings ensure precise forming and excellent surface quality of the finished parts.

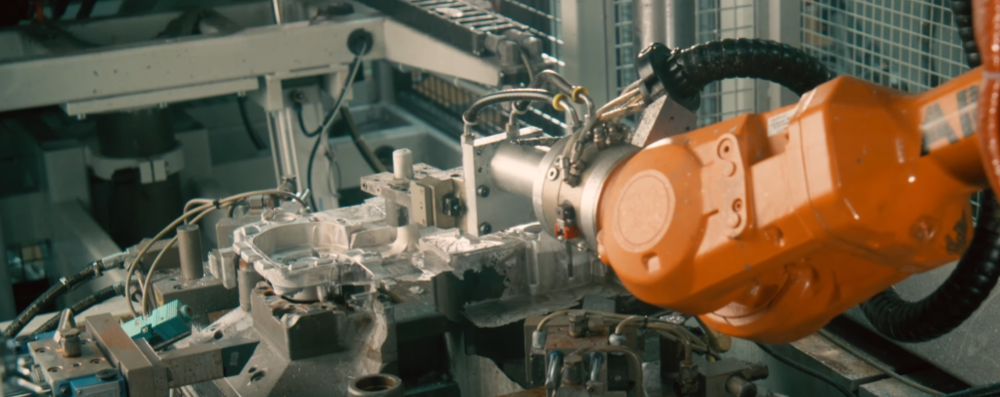

Once the mold design and process parameters are finalized, the actual magnesium die casting can begin. Our experienced operators strictly follow the established procedures at every stage, ensuring accuracy and production stability.

Melting and pouring are critical steps in the magnesium die casting process. JUNYING precisely controls furnace temperature and melt composition to guarantee the quality of the molten metal. During pouring, the molten magnesium is quickly and accurately injected into the mold to prevent premature solidification.

After die casting, the parts undergo various post-treatment and surface finishing processes, such as trimming excess material, degassing, sandblasting, and precision machining. These steps enhance the quality and surface finish of the final products.

The final step involves rigorous inspection and testing of the die cast products. We use methods such as X-ray flaw detection, ultrasonic testing, and hardness testing to check for any defects, ensuring that all products meet or exceed design specifications and customer requirements.

Magnesium die casting offers a number of performance and manufacturing benefits:

JUNYING’s strict process control and commitment to quality guarantee reliable, high-precision magnesium die cast parts for automotive, aerospace, electronics, and many other industries.

Magnesium die casting finds use across a broad spectrum of industries due to its unique combination of low weight, strength, and design flexibility. Common applications include:

Production plants dedicated to magnesium die casting, such as advanced facilities in Europe, routinely supply components to global assembly plants for use in chainsaws, power tools, and more.

Magnesium used in die casting is rarely pure; it is alloyed with elements including aluminum, zinc, manganese, silicon, and rare earths to achieve specific characteristics. The industry commonly follows ASTM guidelines for designating magnesium alloys. These designations use two capital letters to indicate the two main alloying elements, listed in order of their proportions, followed by numbers indicating their relative content. Popular die casting alloys include AZ91, AM60, and others, each offering a balance of mechanical and physical properties suited to specific applications.

AZ91D

The most commonly used magnesium alloy for die casting, offering the best overall performance. It is suitable for large-scale, precision die-cast parts in industries such as automotive and electronics.

AM60/AM50

These alloys feature higher ductility and toughness, making them ideal for components that require greater impact resistance and plasticity, such as automotive seat frames and wheels.

AE42

This alloy has excellent corrosion resistance and is suitable for parts used in high-temperature, high-humidity, or corrosive environments.

| Alloy Type | Al (%) | Mn (%) | Zn (%) | Si (%) | Cu (%) | Ni (%) | Fe (%) | Others (%) |

|---|---|---|---|---|---|---|---|---|

| AZ91D | 8.3–9.7 | 0.15–0.50 | 0.35–1.0 | ≤0.1 | ≤0.03 | ≤0.002 | ≤0.005 | 0.02 |

| AM60B | 5.5–6.5 | 0.24–0.60 | ≤0.22 | ≤0.10 | ≤0.03 | ≤0.002 | ≤0.005 | 0.02 |

| AS41B | 3.5–5.0 | 0.35–0.70 | ≤0.12 | 0.5–1.5 | ≤0.02 | ≤0.002 | ≤0.0035 | 0.02 |

| Alloy Type | Tensile Strength (MPa) | Yield Strength (MPa) | Compressive Strength (MPa) | Shear Strength (MPa) | Fatigue Strength (MPa) | Impact Strength (J) | Elongation (%) | Hardness (BHN) | Young’s Modulus (GPa) | Poisson’s Ratio | Specific Heat (KJ/kg·K) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AZ91D | 230 | 160 | 165 | 140 | 70 | 2.2 | 3 | 75 | 45 | 0.37 | 373 |

| AM60B | 220 | 120 | 130 | 100 | 70 | 6.1 | 6–8 | 62 | 45 | 0.35 | 373 |

| AS41B | 215 | 140 | 140 | N/A | N/A | 4.1 | 6 | 75 | 45 | 0.37 | 373 |

| Alloy Type | Density (g/cm³) | Solidus (°C) | Liquidus (°C) | Melting Range (°C) | Specific Heat (J/kg·°C) | Thermal Expansion (μm/m·K) | Thermal Conductivity (W/m·K) | Electrical Resistivity (μΩ·cm) | Electrical Conductivity (MS/m) | Coefficient of Friction (mm/N) |

|---|---|---|---|---|---|---|---|---|---|---|

| AZ91D | 1.81 | 470 | 595 | 625–700 | 1.05 | 25.0 | 72 | 14.1 | 6.6 | 0.35 |

| AM60B | 1.79 | 540 | 610 | 650–695 | 1.07 | 26.2 | 62 | 12.5 | 7.1 | 0.31 |

| AS41B | 1.77 | 565 | 620 | 660–695 | 1.02 | 26.1 | 68 | N/A | N/A | 0.35 |

Comprehensive Capabilities in Magnesium Die Casting

JUNYING provides an integrated solution for magnesium, aluminum, and zinc alloy die casting, covering everything from mold design and manufacturing to precision casting, CNC machining, and complete surface finishing. With die casting machines ranging from 88T to 1250T, JUNYING can accommodate both intricate small parts and large components up to 1 meter, meeting the diverse needs of industries such as automotive, electronics, medical, and drones.

Rich Experience and Professional Customization

With over 10 years of industry experience, JUNYING has served thousands of products and projects, delivering customized magnesium die casting solutions based on client drawings or samples. The company’s engineering team precisely manages complex projects, ensuring every detail meets customer requirements for lightweight, high-strength, and shock-absorbing magnesium alloy parts.

Industry-Leading Quality Control

JUNYING is certified to ISO9001 and IATF 16949 (automotive industry quality management), mirroring the rigorous supplier qualification standards seen at Xometry. Every stage of production, from material selection and melting to casting, machining, and surface treatment, is closely monitored. Advanced inspection equipment and standardized processes guarantee stable quality and consistency for every batch.

Advanced Technical Capabilities

JUNYING’s magnesium die casting process leverages both hot chamber and cold chamber casting methods to optimize for part complexity, volume, and cost, just like leading global suppliers. The company utilizes protective gas atmospheres and advanced temperature controls to ensure casting safety, material efficiency, and reduced oxidation risk, delivering parts with excellent mechanical properties and surface quality.

Diverse Surface Finishing Options

Surface finishing options include electroplating, powder coating, sandblasting, and painting, allowing magnesium parts to meet stringent requirements for appearance, corrosion resistance, and surface performance across high-end industries like automotive, electronics, and medical devices.

Efficient Project Management & Reliable Lead Time

Guaranteed lead times: quick mold fabrication and prototyping, and as fast as 7 days for bulk production. Each project is assigned a dedicated manager who provides round-the-clock communication and transparency throughout the manufacturing process, ensuring on-time delivery and seamless project execution.

One-Stop, Turnkey Service

From initial design consultation and mold development to mass production and final shipment, JUNYING provides a true one-stop service. Customers benefit from efficient communication, flexible customization, and end-to-end project management—streamlining procurement and reducing time-to-market.

Sustainability and Recyclability

Magnesium alloys are lightweight, recyclable, and environmentally friendly. JUNYING’s expertise helps clients reduce carbon footprint and improve overall product sustainability—aligning with modern green manufacturing trends.

1. Material Properties

2. Die Casting Process

3. Applications & Cost

| Aspect | Magnesium Die Casting | Aluminum Die Casting |

|---|---|---|

| Density (g/cm³) | 1.74–1.85 | 2.7–2.8 |

| Tensile Strength | 150–250 MPa | 310–570 MPa |

| Min. Wall | 0.6 mm | 1.2–1.5 mm |

| Corrosion | Needs protection | Excellent (natural oxide layer) |

| Thermal Conduct. | ≥120 W/(m·K) | Lower |

| EMI Shielding | Excellent | Good |

| Mold Life | 100,000–150,000 shots | 50,000–80,000 shots |

| Raw Material Cost | ¥12–15/kg | ¥1.5–2.0/kg |

| Applications | Lightweight, 3C, EMI, auto dashboards | Structural, high-strength, auto frames |

Which Is Better to Choose for Your Project?

1. Passivation Treatment:

Passivation is one of the most common surface treatment processes for magnesium alloy die castings. It mainly forms a dense passivation film on the surface of the magnesium alloy die casting, improving its corrosion resistance and wear resistance. It can also enhance the adhesion of additional surface treatments such as powder coating or painting. For products without high appearance requirements, passivation is a basic and essential treatment method.

2. Powder Coating:

Powder coating involves evenly spraying powder coating material onto the surface of the magnesium alloy die casting, then curing it through heating to form a protective layer. This coating effectively isolates the magnesium alloy from the external environment, providing excellent corrosion resistance, wear resistance, and decorative effects. Powder coating offers a wide variety of colors and textures, allowing for the realization of specific appearance and performance requirements.

3. Painting (Spray Painting):

Painting involves spraying liquid paint onto the surface of the magnesium alloy die casting, which forms a protective film after drying and curing. Similarly, painting can achieve a variety of colors and gloss levels to meet different design needs. For example, in 3C products (computer, communication, and consumer electronics), painting on magnesium alloy housings can create stylish appearance effects while protecting the internal magnesium alloy structure from environmental damage, thus extending the product's service life.

4. Micro-Arc Oxidation (MAO):

Micro-arc oxidation is a surface treatment technology developed based on anodizing. It uses high voltage to generate micro-arc discharges on the surface of the magnesium alloy, causing the surface oxide film to further grow and densify under high temperature and pressure. The thickness can reach tens to hundreds of microns, offering higher hardness, wear resistance, and corrosion resistance. For example, in the aerospace field, micro-arc oxidation treated magnesium alloy components can withstand high-speed airflow erosion and the harsh environment of space.

5. Electroplating:

Electroplating includes treatments such as nickel plating and chrome plating. Nickel plating forms a nickel metal layer on the surface of the magnesium alloy, which has excellent corrosion resistance and decorative properties, giving the surface a bright metallic appearance. Chrome plating forms a chromium metal layer, which is hard, wear-resistant, and highly reflective, making the magnesium alloy surface look even brighter.

These are some of the common surface treatment processes for magnesium alloy products. Different products can choose different surface treatments according to their specific requirements to achieve the desired appearance and performance.