Robots and artificial intelligence (AI) are the core of the new era of manufacturing industry, and also the driving force to promote the development of gravity casting digital industry. Robots and artificial intelligence play a universal and important role in many industries – improving accuracy and consistency, reducing production and improving product quality. More and more metal manufacturing factories and laboratories are using robots and artificial intelligence technology to improve efficiency and connectivity.

The Rise Of Robots: 3 Major Trends Of Metal Gravity Casting Industry

The survey results show that as early as 2014, 59% of global manufacturers used robot technology in some form. According to the World Robotics Statistics Report, by 2017, driven by the abnormal growth of the metal manufacturing industry (+55%), the sales of industrial robots had increased at an annual rate of 30%. Today, as our production is getting closer to full automation, the demand is also further accelerating. Our work efficiency is increasing, and the injury and worker fatigue are continuously reduced. Here are three major trends we have found in the field of metal manufacturing about how robots change their ways:

1. Creating efficiency – the rise of cooperative robots

At present, manufacturing enterprises at home and abroad have to face not only the growing material needs of consumers, but also the challenges brought by resources and environment. Therefore, depending on the current level of manufacturing technology is not enough to meet the material needs of consumers and cope with the negative impact of the environment. In order to properly deal with such problems and solve the bottlenecks faced by the manufacturing industry, it is necessary to carry out a scientific and technological reform of the manufacturing industry. With the continuous progress of science and technology and the rapid development of the new generation of information technology, mainly the Internet, big data and the Internet of Things, various modern and intelligent technologies are more and more widely used in the manufacturing industry, promoting the continuous innovation and development of the manufacturing industry, and also becoming a powerful driving force of the new industrial revolution. As the key technology of the new industrial revolution, intelligent manufacturing not only has a significant change in the development concept compared with the traditional manufacturing industry; In terms of manufacturing mode, the intelligent manufacturing is realized by integrating ICT technology. Of course, the new generation of manufacturing technology is still in the stage of development and continuous exploration, but it has made a fundamental leap over the development path, system and industrial form of the manufacturing industry, and promoted the manufacturing industry to a new era.

In addition to introducing fully automated production lines, some industries have also introduced collaborative robots, which can work with people. Facts have proved that the manufacturing team composed of humans and robots can fill human idle time and significantly improve overall efficiency.

Today, many manufacturers are facing the challenge of labor shortage in foundries. On the contrary, we found that robots can take on dirty, boring and dangerous tasks, and then provide more opportunities for their human “colleagues” to deal with higher-level tasks, and provide more consistency to improve quality.

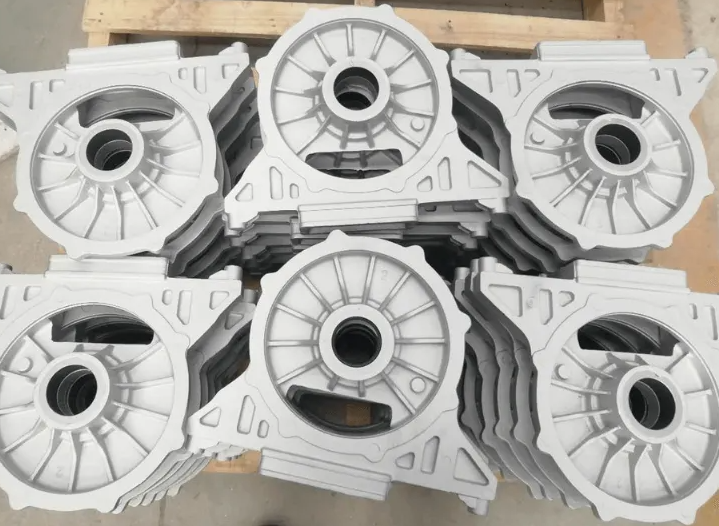

Another example is large parts manufacturers (such as castings and frames for trucks, off-road vehicles and agricultural, construction and mining equipment). Under normal circumstances, the capacity of such manufacturers is limited, and they cannot manufacture and move parts weighing 500 kg quickly, stably and safely. Therefore, large parts manufacturers have turned to robots for machine loading and unloading, parts handling, welding, painting and assembly to improve production capacity and quality.

2. All-weather plant and laboratory

In the process of metal manufacturing, the robot can be programmed to operate all day long without anyone on duty, so as to realize completely uninterrupted production. In a world where “green” manufacturing or sustainable manufacturing practices are constantly advocated, the strength of robots lies in their ability to work in dark and cold environments, thus saving costs and energy.

With the development and popularization of the Internet, manufacturing has become more and more digital and virtual, and many creative technologies will also be carried out in virtual space. Although the physical manufacturing of proprietary technology can be protected by intellectual property rights, the resources in the digital space may be highly transparent, which allows enterprises to share resources with each other. At present, the shared resource model has achieved phased success in other industries, such as shared cars and shared bicycles to alleviate traffic pressure and reduce private car travel, and shared industries such as Airbnb in the field of accommodation services. Therefore, in the field of intelligent manufacturing in the future, there will also be sharing modes of shared manufacturing equipment, software, knowledge and shared collaborative modeling.

In addition to manufacturing equipment, transportation is also a very important resource in the manufacturing industry, and any manufacturing cannot be separated from transportation. Transportation can be divided into two categories:

External transportation is mainly to provide supply services and external distribution services for the company’s products; Internal transportation mainly refers to the transportation of materials in the production process. From the perspective of manufacturing, both external transportation and internal transportation are non-value-added activities. However, the distance of transportation is relatively fixed. Therefore, an idea that can reduce transportation costs is triggered, that is, shared transportation: a transportation network that connects manufacturing with supply and distribution through the Internet, which can provide an optimal solution for multiple supply ends and distribution at the same time. The utilization of resource sharing is undoubtedly one of the important factors to promote the development of manufacturing industry.

The robot can identify the materials flowing into and through the factory or laboratory in the workshop, test the samples to ensure quality control – real-time feedback between the operator and the laboratory results, so that the operator can react in a few minutes, and some operators may make necessary adjustments without leaving the post. Robots can do all hard work without feeling tired – machines can work as hard as analytical instruments.

3. Cloud robot technology

Cloud robot technology is an emerging field that enables robots to combine robot functions with other digital tools such as artificial intelligence and virtual reality. Cloud robot technology can also enable robots to share information and real-time data while connecting to the cloud.

“Cloud manufacturing” is an innovative manufacturing method, which refers to the transformation of manufacturing resources into a shareable and customer-centric advanced manufacturing mode with the support of the Internet of Things and service-oriented technology. It uses on-demand access and distributed manufacturing to achieve optimal resource loading response and improve product manufacturing efficiency. At the same time, it also covers the entire life cycle of products from design, manufacturing, testing to maintenance. Therefore, it is also called a manufacturing system integrating intelligent production and management.

In cloud manufacturing, we use virtualization technology to upload production resources to the cloud service system, use relevant Internet technology to classify and package the uploaded resources, and provide users with various services such as accessing and invoking resources to realize the sharing and circulation of resources. It also promotes the development of cloud manufacturing and provides technical support for intelligent manufacturing.

In the metal manufacturing industry, information plays a leading role. Cloud robot technology has the ability to ensure manufacturing quality and make the control process simpler and faster. This is why we specially design software for users, because this technology can quickly and conveniently send, store and retrieve analysis results in cloud-based services, including managing a group of instruments from a certain location.

“Big data” refers to a collection of data that cannot be processed with conventional data processing methods within a certain period of time due to its wide range, large scale and complex structure. With the rapid development of Internet technology, data acquisition is everywhere, and big data comes from all aspects of life. Therefore, special technologies and methods are needed to predict and analyze big data and extract valuable data from it. In this context, big data analysis technology has gradually taken shape. Although modern tools (such as intelligent sensors) can easily obtain data, to realize intelligent manufacturing, it is necessary to effectively process the data in each link of product development so as to obtain the correct information in the determined development link. Therefore, the key of big data analysis technology is whether the data can be correctly processed and utilized, which is crucial to the realization of intelligent manufacturing.

But who can say that in the near future, with the development of technology, these tasks will not be completed by robots?